· Manganese oxide ore beneficiation methods to reelect based. Weathered oxide ore often contains a lot of sludge and fine ore, production on the use of a washing method for reelection. Ore mine Jingxi remove sludge, the net mine, and some can be used as finished ores, and some need to use jigging and shaking so on reelection.

crushing of electrolytic manganese ore

Apr 27, 2016 Crushing and Sampling of Manganese Rock The flowsheet incorporates a conventional multistage crushing plant with a grizzly or screen ahead of both the primary and secondary crushers The mine run ore is dumped through a 10″ grizzly into a coarse ore bin The ore is discharged by a Apron Feeder to feed the primary Jaw Crusher

Manganese Market Growth, Trends, COVID19 Impact, and Forecasts (2022 2027) The Global Manganese Market is Segmented by Appliion (Alloys, Electrolytic Manganese Dioxide, Electrolytic Manganese Metals, and Other Appliions), Enduse Sector (Industrial, Construction, Power Storage and Electricity, and Other Enduse Sectors), and Geography .

Electrolytic manganese dioxide (EMD): a perspective on worldwide production, reserves and its role in electrochemistry. Avijit Biswal abc, Bankim Chandra Tripathy bc, Kali Sanjay bc, Tondepu Subbaiah bcd and Manickam Minakshi * a a School of Engineering and Information Technology, Murdoch University, Murdoch, WA 6150, Australia. Email: minakshi; Tel: .

Manganese dioxide is prepared either chemically or electrolytically. Exhibit 7 illustrates the electrolytic production of manganese dioxide, which is similar t o the electrolytic production of manganese metal. Manganese ore and coke are reacted in kilns at 600°C. The mi xture is cooled and leached with a solution containing 50 grams per liter of

Crushing Of Electrolytic Manganese Ore. The crushing and sampling plant is designed to operate on a one shift per day basis with a capacity of from 400 to 500 tons per shift. The excess crushing capacity is to allow for the stockpiling of excess available ore and to take care of the operation on one shift.

Hydrometallurgy is the most suitable extractive technique for the extraction and purifiion of manganese as compared to all other techniques including biometallurgy and pyrometallurgical processes. In the hydrometallurgical processing of manganese from its ore, the leach liquors often contain divalent ions such as iron, manganese, copper, nickel, cobalt and zinc along .

· Generally speaking, manganese ore is divided into manganese carbonate ore and manganese oxide ore. Most manganese ores are embedded with fine or microfine grains, and the content of high iron ore, high phosphate ores and associated beneficial metals is high, so manganese ore beneficiation is still quite difficult.

Grade Egyptian Manganese Ore via Hydrogen at 800˚C 950˚C. Open Access Library Journal, 1: ... Chemicalgrade has various specifiions depending on the specific end use such as feedstock for electrolytic manganese and manganese dioxide, manganese ... and cold crushing strength of the briquette (the pressing load is constant = ...

· China's electrolytic manganese metal production is mainly % of the products (now most of the manufacturers have actually reached % or more), only a few manufacturers produce % of the products (because of % of the product market demand is small, but many enterprises in the feasibility study report are known as the production of %), The .

Production Process Of Electrolytic Manganese Metal. Mar 12 2013 Manganese ore powder react with the inorganic acid heating to prepare manganese salt solution Added the ammonium salt as buffer to the solution at the same time remove iron with the method of adding addition to oxidize add cleaning agent to remove heavy metals and then separation and filtration Add .

this mining operation The process is currently unprofitable with a gold price around 300 per ounce Process Description Unit 100 – Size Reduction of Ore The BFD of the overall process is shown in Figure 1 The PFD for Unit 100 shown in Figure 2 is designed to reduce 415 tonshr of gold ore from a feed range of 25" to 160 microns

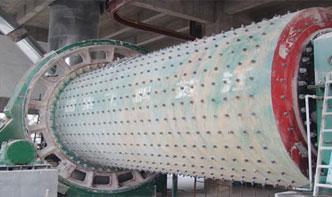

manganese ore processing flow. Manganese ore processing technology is usually divided into three stages: crushinggrindingbeneficiation. The required manganese ore processing equipment includes jaw crusher, cone crusher, ball mill, magnetic separator, dryer and other equipment. The following is a detailed process flow introduction.

· The Manganese Ore Processing Plant Crushing and Sampling of Manganese Rock. The flowsheet incorporates a conventional multistage crushing plant with a grizzly or screen ahead of both the primary and secondary crushers. The mine run ore is dumped through a 10″ grizzly into a coarse ore bin.

After passing Chemical Engineering In year 1977 he join Manganese Ore Mining business with his father and after successful in Mining business Mr. Chauhan decided to take up another challenging project of producing high grade Manganese Ore Powder, Manganese Dioxide Powder and Calcined Maganese Ore Powder.