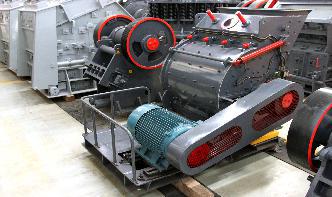

This paper addresses the critical design parameters as well as the consideration of ore characteristics, geographical loion, climatic conditions, expected operational life, expansion potential, safety, environment, and operability and maintainability. INTRODUCTION The fundamental goal for the design of a crushing plant is an installation that meets the required .

design parameters for feeders crushing

Design Modifiion of Failure Mode Effect Analysis of Vibrating Feeder used in Crushing Industries Prashant Salat1 Amit Anakiya2 Student 2Assistant Professor 1,2Department of Mechanical Engineering 1Gujarat Technological University, India 2Veerayatan Group of Institutions, India Abstract— Vibratin feeder technology is common in material handling .

20/02/2019 · Vibrating Feeder is also known as vibrating feeding machine; it could put lumpish, granular materials into material accepting device uniformly, timely and continuously from silos during the production process, it could feed for crusher machinery continuously and evenly in gravel production line, and coarse screening the material, widely used in the crushing and .

Design Parameters For Feeders Crushing. Design Parameters For Feeders Crushing. Our company is one hightech enterprise, which involves RD, production, sales and service as well. In the past 30 years, we devote to producing mining equipments, sand making machines and industrial grinding mills, offering expressway, rail way and water conservancy projects the .

03/01/2022 · The introduction of a slide gate in the primary silo of the crushing circuit is an alternative to increase the degree of freedom for controlling the fresh ore flowrate. This paper presents a numerical simulation using a discrete element method (DEM) applied in a silogatefeeder system. The simulated model is based on parameters from a Vale's ...

The client determines both parameters: PS k=0 = PS 0 (t/h) and k=0 = 0 (mm). Primary feeders or PFs (M 1) dose the exact production required in the extruder. Each feeder draws a variable production P k=1 (t/h) from its hopper. The total stage production must be equal to PS 0, but the production of each feeder may

17/03/2022 · Study on the Mechanical Properties and Design Parameters of Floor Slabs Waste Subgrade Filler. Chenglin Shi,1 Yong Wang,1 Chunli Wu,2 and Wenzhu Song3. 1College of Transportation Science and Engineering, Jilin Jianzhu University, Changchun 130118, China. 2College of Transportation, Jilin University, Changchun 130022, China.

design parameters for feeders crushing. Our products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials leading products have crushing equipment, sand making equipment, mobile crusher, etc., Each type of product is with complete specifiions. All products have passed .

12/06/2019 · Vibrating Grizzly Feeder. Feed Capacity. The capacity of vibrating grizzly feeders is calculated according to the following formula: Q=3600 x f1 x f2 x f3 x L x H x V. where, Q=Feed Capacity in (m3/hr) To obtain capacity in Tons per Hour, multiply by bulk density of the material. Qt = Q x bd bd = Tons/m3 for sand and crushed stone; f1 is the Size Factor f1 = 1 for .

parameters for aggregate screening efficiency. Design Parameters Of Vibrating Screen In UK aggregate crushing plant the principle design parameters Design Parameters For Feeders Crushing Chat With Sales Dynamic design theory and appliion of large vibrating The reliability is a key factor for the ...

Design Parameters For Feeders Crushing. Electrical design parameters of crushing plant safe crushing screening plant design safequarry on mobile and stationary crushing and three stage plant an example of operator comfort to maintain these parameters are shown in the picture levels safe pra. 【Get Price】 Pid And Predictive Pid Control Design For Crushing .

Plant Design and Configuration. Introduction. Having looked at the various individual components – crushers and crushing; feeders and screens; washing, dewatering, silt/slimes treatments; and conveyors. This PDP will assemble those components into a complete plant. This can never be a straightforward process, as any individual plant will be ...

01/07/2021 · The calibration of DEM parameters was performed using the observed angle of the pile formed on the conveyor (surcharge angle). Various feed chute designs were then employed in the simulations based on an experimental design to find more uniform feed distribution on the distribution plate of the crusher. More uniform feed distribution was obtained by changing the .

19/07/2018 · Based on the theoretical design, it was found that the main shaft speed of rpm transmitted by a belt drive from a three horse power electric motor is .

use of OEE for granite crushing plant, though; attempts have been made to use the metric on drilling machines, loading and haulage facilities. This paper presents a procedure for estimating OEE of a crushing plant; explains the cause for poor OEE in Nigerian plants during rainy season; and reason why Nigerian crushing plants should run with generators of adequate power .

design parameters for feeders crushing Design Parameters For Feeders Crushing . The initial parameters were to design a machine to handle in excess of 1,500t/hr Within maximum Apron plate feeders for crushing plants To complement the » Chat. crushing feeders Design Parameters For Feeders Crushing, design parameter or .

crushing plant design. The main parameters are used from crushing plant design theory, ... performance reaches a maximum level at a certain feeder target feed rate. This is where . .

design calculation of vibrating feeder pdf. ... lations are design parameters of the conveyor, ... crushing and screening plants for sale canada; Vibrating Feeder Design Software Mining Machinery. vibrating feeder design parameters. Vibratory Feeders in ... machine pdf XSM is a leading global manufacturer of crushing and. Software Design For ...

Crusher Capacity Parameter cone crusher has advantages of large crushing ratio, high efficiency, high capacity, low operation cost, easy to adjust, economic and other characteristics. Due to the better materials selection and structure design, it has a longer service life, and crushed product has more uniform size. Jaw Crusher Working Principle. Metallurgical .

Design Parameters For Feeders Crushing; Provide professional mining equipment. Crushing plant design and layout considerations,the principal design parameters that drive crushing plant selection and configuration include: production requirements capital cost chutes must be easily accessible for cleanup, and large feeder openings must be provided for bins, silos and .

design parameters for feeders crushing . Crushing Plant Design and Layout Considerations. General Primary crushing Fines crushing Storage reclaim Maximum rock size in the feed Ore types, compressive strengths and abrasion indices Ore specific gravity Ore bulk density Ore moisture, wet season Ore moisture, dry season Angle of repose Angle of withdrawal Angle of .

Key silo design parameters; Discharge diameter (avoids arching and ratholing) The discharge angle: The volume of the silo: The discharge rate from the silo : Calculating the silo discharge diameter with the method of Jenicke. The flow of powder in a hopper is linked to 3 properties : The powder internal friction : how easy the powder particle can move from each other; The .

Design Parameters For Feeders Crushing. Vibrating Screen Design Parameters Jul 15, 2018 An analysis of screen design options on the operating efficiency of secondary crushing plants has been conducted using a dynamic computer model. The model allows for the simulation of a wide variety of crushing circuits and can be run on either a microcomputer (IBM PC XT) or a .