improved performance with advanced wear materialsin. Appliion in a coal mill CE803XRP. In the coal fired power industry the mill operation is mainly driven by the coal fineness to optimize combustion performance and minimize carbon carryover (unburned carbon) and assisting to maintain environmental performance (particulate and NOx).

how to improve coal mill fineness

LM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing nonmetallic minerals, pulverized coal and slag. Its coverage area is reduced by 50% compared with ball mill, and the energy consumption is .

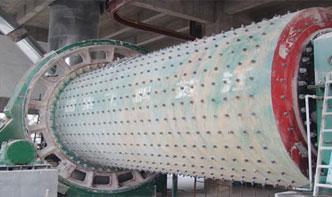

Mar 18, 2021 · The grinding effect of the ball mill directly affects the grinding efficiency and the output of the ball mill. In addition to considering the size of the ball mill, internal structure of the ball mill, product fineness requirements and other factors, should also consider the characteristics of the grinding material, such as grindability, particle size, etc.

desired fineness of the coal mill Desired Fineness Of The Coal Mill Pulverized Coal Pipe Testing And Balancing The next step in this plant is to upgrade the mill to improve coal fineness to 75 passing a 200mesh sieve pulverizers prepare the raw fuel by grinding it to a desired fineness and mixing it Desired Fineness Of The Coal Mill. read more.

The coal is then proportionately mixed if required to get uniform desired quality. This coal is then fed into dump hopper to feed in the ball mill where it is pulverized to desired fineness at 12 – 13 TPH and stored in fine coal bins for PC and Kiln firing.

Dec 11, 2021 · mill fineness sapling probe method. coal mill fineness sampling instruments. Pulverized Coal Pipe Testing and Balancing The isokinetic coal sampling method although more difficult is the best option for determining the true mill coal fineness produced and to calculate pulverizer performance we perform isokinetic coal sampling after the dirty air velocity probe .

Coal mills grind the coal to required fineness and primary air dries and supplies the pulverized fuel to the burners. The dynamic response of coal mills is poor due to simple controls and various ...

Improve The Production Efficiency Of Ball Mill. 5 ways to improve the ball mill efficiency fote compared with other ball mills that used for the same period his ball mill grinding efficiency is higher by about 25 at present the capacity of the gold ball mill is 180tph the particle size of the feed is controlled at about 20mm and the output easily reaches 200 mesh how to.

Jul 23, 2018 · Chaeng high grinding process coal vertical mill News Date: 15:35:40. The coal vertical mill has less dust, low noise, high efficiency granular composition, and excellent combustion performance due to its special design and structure. Chaeng Vertical Roller Mill has simple process, compact structure, product fineness of 80μmR 3%, with steady and average .

How To Increase Fineness Of Coal Mill. Grinding fineness of ball mill of ball millgold mining equipment coal mining to reduce the beneficiation costs and increase the economic tyy lxp how improve coal mill fineness in india ball mill type used to increase fly ash fineness 25 sep 2013 airswept coal mill plays a vital role in cement production 28.

Feb 20, 2021 · In addition, the adjustment of the fineness will change the output. The motor power of the main engine and the blower can be appropriately increased to increase the output. Secondly, The Adjustment Of The Swing Position Of Grinding Roller. Inside the mill, the grinding roller is one of the important parts for grinding limestone.

Ethiopia Improve Performance Of Table And Roller Mills For. Coal Pulverizer Design Upgrades to Meet the Demands,result in additional wear on roller and table segments and will produce excessive mill vibration While at high mill load operation the grinding force is insufficient to meet the requirement for mill load increase o 180 160 140 120 100 Opera ion curve s ring mill 120 .

Production Fineness: S95. Zincgermanium slag and matte slag can be used to recover metals. (2) Slag powder supply to cement plant or mixing station . Production Fineness: S105. Steel slag, water slag, manganese slag, nickeliron and coal slag can be used as admixtures for concrete mixing station after grinding. The Main Uses:

The original cement plant has only one grinding mill and ball mill, the production capacity is seriously insufficient. In order to improve the quality control ability of the cement plant and respond to the national energy conservation, emission reduction and energy consumption reduction, this renovation aims at the current situation ...

How To Improve Coal Mill Fineness Exodus Mining Machine. Keywords pulverizer mill exhauster coal feeder maintenance reliability it is intended to improve the maintenance practices and reliability of the equipment greater degree by the air quantity and fineness of the coal going to the furnace vii an alstom How To Improve Coal Mill Fineness.

Oct 07, 2010 · The next step in this plant is to upgrade the mill to improve coal fineness to 75% passing a 200mesh sieve. Proper Coal Velocity Is Essential.

Effect of the Fineness of Pulverized Coal on the Slagging, Sep 20, 2016· On the understanding that the characteristics of the gas flow have a major contribution to slagging, a change in the fineness of pulverized coal necessitates taking into account the change in the properties of fly ash, which can either improve or worsen the slagging situation

Sep 30, 2021 · Vertical mill for coal gangue powder mill. Vertical roller mill equipment is not only a righthand assistant for solid waste residue projects such as coal gangue, slag, water slag and fly ash, but also an important equipment to promote the solid waste residue market to realize the value of recycling. HCMilling(Guilin Hongcheng) adopts a new ...

Significance Of Coal Mill Fineness. desired fineness of the coal mill ME Mining Machinerydesired fineness of the coal mill Desired Fineness Of The Coal Mill. Pulverized Coal Pipe Testing And Balancing The next step in this plant is to upgrade the mill to improve coal fineness to 75 passing a 200mesh sieve pulverizers prepare the raw fuel by ...

Mill maintenance costs are one of the highest maintenance costs in a coal fired power station; Testing allows a change to 'condition based' maintenance (from set mill operating hours) which in HRL's experience can increase time between minor / major mill overhauls by up to 10%;

Coal mill also called coal pulverzier or coal powder mill is grinding mill that is used in coal mining 5 increase the fineness of the coal from 10 to 15 online chat how to. ... cachedball mill type used to increase fly ash fineness coal ball mill type used to increase fly ash fineness get price adb db and daf in coal mining.

how to improve coal fineness. Al mill made in chile fineness how to improve coal mill fineness lemine mining how to improve coal fineness in xrp 763 coal bowl mills span class b the raw coalso that the pulverised product at desired fineness can fed to .

Determination Of Coal Mill Fineness. Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc. SBM is one of the biggest manufacturers in Aggregate Processing Machinery for the analysis of coal mill ...