Ball mill specific grinding rate 29 Ball mill grinding efficiency 33 Progress Review 1 39 PART II Functional Performance Analysis 43 Using the functional performance equation 43 Functional performance efficiency 47 Relating design and operating variables to grinding, classifiion, and circuit efficiencies 53

ball mill grinding efficiency

crushing and less grinding, reducing the feeding particle size of ball mill. The larger feeding particle size is, the greater the work done by the ball mill on the ore, which impacts the grinding efficiency. To reach the eligible grinding fineness, the workload must increase. The energy consumption is also increasing.

· In production, controlling grinding concentration is through controlling the feeding amount, water supply, or adjusting the particle size composition of graded returned sand of control classifiion, helping increasing ball mill grinding efficiency. ball .

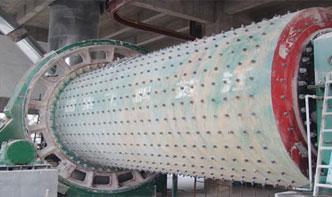

· Practical 1: Title: Ball Milling Objective: To grind the coarse salt to a smaller size by using a ball mill and to obtain the particle size distribution of the initial and the sieved final mixture. Introduction: 'Ball milling is a method used to break down the solids to smaller sizes or into a powder. A.

· Ball mill's low grinding efficiency, low processing capacity, high production energy consumption, unstable product fineness, etc. are problems that many customers will encounter. How to effectively improve the grinding efficiency of the ball mill is an important issue. Now, let's share 10 ways to improve the grinding efficiency of the ball mill!

· As a kind of highefficiency and energysaving ultrafine crushing equipment, the sand mill has developed rapidly in the past ten sand mill mainly realizes the grinding of objects using friction, shearing, collision, etc. It is currently one of the grinding equipment with the widest range of material size and

They dominate these grinding appliions because greater stress intensity can be delivered in stirred mills and they can achieve better energy efficiency than ball mills in fine and ultrafine ...

· Through the long period operation, ball mill meets the problem of grinding efficiency descending. It impacts the normal operation of processing plant, and also causes economic losses.

Efficient ball mill is the use of a special device, make the ball mill cylinder generated both revolution and rotation to drive the grinding media .. Bond also described its appliion for measuring grinding circuit efficiency. .. kWh/t, and the ball mill test done with a closing screen of 150 um yielded a value ..

Answer: As is known by us, the ball mill has a wide range of appliions among so many mining machines, with the highest working efficiency. But what reasons lead to the good reputation of the ball mills? Here our experts will tell you the secret of .

· The first two Grinding Efficiency Measurement examples are given to show how to calculate Wio and Wioc for single stage ball mills. Figure 1. The first example is a comparison of two parallel mills from a daily operating report. Mill .

Factors Affecting Ball Mill Grinding Efficiency. The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed .

Increases in grinding efficiency with increasing ball mill diameters makes the gain in potential capacity slightly greater than the increase in power drawn as mill diameters increase W2 (D2)2"3 WI(D1) (4) As mill diameters increase the potential capacity per unit of mill volume increases with the mill diameter to the exponent w2/y (D May 10 2019 · Grinding mill medium is the .

· Five Factors That Improve Productivity of EnergyEfficient Ball Mill Machines March 17, 2022 agico News As we all know, the energysaving Ball Mill is the most widely used grinding and mixing machine in modern times.

Optimization of the Cement Ball Mill Operation. Optimization addresses the grinding process, maintenance and product quality. The objective is to achieve a more efficient operation and increase the production rate as well as improve the run factor. Consistent quality and maximum output with lower specific power consumption results in lower ...

· 2. Effect of Grinding Mill on Grinding Efficiency. After determining the nature of the ore, the second step is to choose a right grinding mill. As far as the internal structure of the grinding mill is concerned, it can be roughly as follows: 1) the medium of grinding mill. Commonly used grinding media are: steel balls, steel rod and gravel.

Drivers of grinding energy transfer to ore in ball mills • Charge density –charge shape and liner design • Charge surface area • Pulp density rheology • Media mass • Classifier efficiency How can we increase the grinding surface area? 1. Increase the grinding surface • Smaller ball media, or • Different media shape 2.

Ten Ways to Improve the Grinding Efficiency of Your Ball Mill There are a lot of problems that most mineral processing plant will meet when operating the ball mill, such as low grinding efficiency, low processing capacity, high energy consumption, unstable product fineness of the ball mill. So h...