Jul 14, 2017 · Mechanical cleaning or "washing" is actually the process of separation of noncoal materials or undesired adherent materials of coal by using a liquid medium. The liquid medium may be an ...

coal washing process

Jul 18, 2007 · Some clean coal technologies purify the coal before it burns. One type of coal preparation, coal washing, removes unwanted minerals by mixing crushed coal with a liquid and allowing the impurities to separate and settle. Other systems control the coal burn to minimize emissions of sulfur dioxide, nitrogen oxides and particulates.

Coal Washing. Coal washing is a process designed to separate the coal particles based on size, density and shape. Achieved by allowing the coal to settle in the wash fluid. Continuous Mining. Continuous Mining is an underground method of extracting coal. The process utilises a machine that is capable of handling the entire extraction process.

The invention discloses a process of coarse coal slime back washing in predesliming dense medium cyclone sorting. Predesliming is carried out on raw coal fed to be washed to obtain plus sieve raw coal and minus sieve coal slime water, and the plus sieve raw coal enters a dense medium cyclone directly to be sorted; hydraulic cyclone grading is carried out on the minus .

Aug 17, 2020 · The washing is needed in order to test the coal for its quality. But the conventional cleaning methods use toxic chemicals that are carcinogenic. Geoscience BC says new research that it has funded has produced a much safer way to wash coal – one that doesn't require harmful chemicals.

Jan 10, 2014 · MCHM is used in washing coal, helping separate the burnable fossil fuel from the unburnable rock and dirt and other impurities. In the taxonomy of chemistry, it's .

The large amount of waste lye was generated during hydrothermal synthetic zeolite from coal fly ash by microwaveassisted heating. The environment will be polluted, if the improper handing of waste lye, and discharged into the surface water. The washing process of the synthetic zeolite was studied in this paper. Rational recycling of waste lye and reduce the amount of it .

A Method for Determining the Partition Curve of a Coal Washing Process. Peter T. Luckie, Theodore Sprang Spicer, Harold Lemuel Lovell. Pennsylvania State University, 1969 Coal washing 318 pages. 0 Reviews. From inside the book . What people are saying .

Jul 08, 2019 · List Of Clean Coal Technologies Techniques. Washing coal – after it is mined to reduce emissions of ash and sulfur dioxide when the coal is burned. Electrostatic precipitators and fabric filters – can remove 99% of the fly ash from the flue gases. Flue gas desulfurization – reduces the output of sulfur dioxide to the atmosphere by up to ...

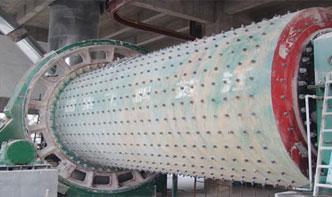

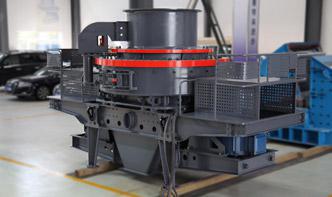

coal washing plant process We provide crushing grinding products and solutions . CRM Mining Crusher is a Porland company with facilities in Europe and Africa that manufactures and installs crushing, grinding, and screening equipment and spare parts for mining, quarrying and demolition operations.

misc{etde_, title = {Tromp dense medium process for coal washing} author = {Schafer, O} abstractNote = {This is a reprint of a paper which first appeared in 1938. It is published as an historical document which is still of considerable interest and it marks a watershed in the evolution of coal preparation processes.

What is the coal washing process? To fluidize a bed of crushed coal and pollutants, the majority of coal cleaning procedures employ upward currents or pulses of a fluid such as water. The lighter coal particles rise to the surface and are washed away from the bed's surface.

Chance Process For Coal Washing Diagram Crusher USA. About Chance Process For Coal Washing Diagram related information:water corporation of western australia. we are the principal supplier of water and wastewater ... >>GET MORE.

Coal cleaning processes / coal washing can either be physical or chemical cleaning and produces refined coal. Physical coal cleaning processes: the mechanical removal of coal contaminants using differences in density are by far the most common processes in use today.

Coal fly ash emitted from coal thermal power plants generally contains tens ppm of arsenic, one of the hazardous elements in coal, during combustion and their elution to soil or water has become a public concern. In this study, the acid washing process developed by the authors was applied to the removal of arsenic from coal fly ash.

Jul 27, 2020 · Floatsink tests are done on samples of coal from beds that will likely need washing (beneficiation, preparation) to remove sulfur or ash (rock and mineral matter) from the coal to meet the desired specifiions of the end floatsink analysis determines how much coal can be separated from rock and minerals in fluids of different densities.

Wash Plant . A processing plant was constructed to process coal to required quality specifiions. The plant is a basic 710 dense media cyclone design and was originally designed to process 60 tonnes per hour (tph), at a yield of ca. 50 – 55%. ... A processing plant was constructed to process coal to required quality specifiions. The ...

Rectisol®, independently developed by Linde and Lurgi, is a physical acid gas removal process using an organic solvent (typically methanol) at subzero temperatures, and characteristic of physical acid gas removal (AGR) processes, it can purify synthesis gas down to ppm total sulfur, including hydrogen sulfide (H2S) and carbonyl sulfide (COS), and carbon dioxide (CO2) .

LZZG washing solutions for Coal washing plant process. LZZG Coal washing plants are mainly used to remove impurities from raw coal or to classify high quality coal and low quality coal. Chat Online; Jigging Process of Aggregates on an Example · rule of optimal use. In Poland jigging is a process used particularly for coal fines processing ...

Coal is also becoming the primary fuel for steam generation for electric utilities. The mechanical coal cleaning process will allow certain coals to be combusted without additional sulfur emission controls and in those situations where such controls are still necessary, prior coal cleaning helps reduce the emission control costs.

The aim of acid washing process is to remove hazardous ele [15] Bool, Helble, A laboratory study of the partitioning of trace ments on the surface of coal fly ash particles by washing with elements during pulverized coal combustion, Energy Fuels 9 .

May 31, 2018 · 2. Coal Usage and Control of CO2 Emissions 3. System Design of Coal Washing 4. Coal Sizing 5. Wet Cleaning Process by Major Unit Operations 6. Dry Cleaning Process . Part II Case studies 7. Coking Coal Washing 8. Fine Coal Washing 9. NonCoking Coal Washing 10. HighSulfur Coal Washing. Part III Sustainable management 11. Emerging ...

Nov 13, 2020 · The term "clean coal" has been applied to many technologies, ranging from wet scrubbers, which remove sulfur dioxide from coalgenerated gas, to coal washing, which removes soil and rock from coal ...

When a microbubble flotation technique was employed to float Appalachian coal, it produced a cleaner coal product than conventional macrobubble flotation;A general kinetic model was proposed to represent the rate of flotation of coal. For two Appalachian coals, the model successfully represented the flotation kinetics of uniformly sized coal.