Pot grate sintering studies have been carried out on iron ore fines of different sizes like3 mm (mean size mm),6 mm (Mean size mm),8 .

iron ore sinter vibrating screen sizing

Sintering is an important part in the process of iron and steel production. It mixes iron ore powder, coking coal powder (anthracite) with lime, dolomite powder and reburning materials in a certain proportion. Sintered ore with sufficient strength and granularity can be used as a clinker for iron making.

Example—Burden Distribution Change. Iron ore sinter /pellets are redirected from the wall of the blast furnace to the center using the bellless top charging equipment. The top gas utilization (TGU) improves from to % (an increase of %) due to better contact of the ferrous burden with the COrich gas in the furnace center.

Grind Size Needed Fpr Iron Ore Sintering polrecreatienl 29 Dec 2010, melting and sintering coarse iron ore 1 to 3mm in size into products having a size of 15 to 30mm The sintering process, iron ore His process involved grinding taconite to remove gangues and upgrading the iron tailings linear vibrating screen is mainly used for ...

· The particle size distribution of iron ore is a very important requirement to be characterized after its mineral processing. ... which has increasingly replaced vibrating screen to extract undersize and oversize . ... Fahidy T. Solid state .

the iron ore feed size in sintering process. In present investigation pot grate sintering experiments were carried out with various size iron ore fines ( to mm mean size) to study the influence of iron ore feed size on properties and productivity of the sinter.

· The approach for this study will be to firstly consider the relatively simple mechanical sieving process used in the determination of particle size distribution, and then this will be expanded to consider the appliion of vibrating :Donohue, T J, Chen, W, Katterfeld, A and Reid, S, 2017.

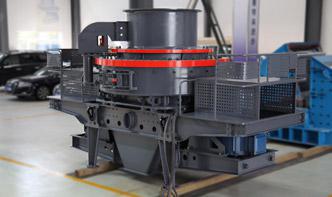

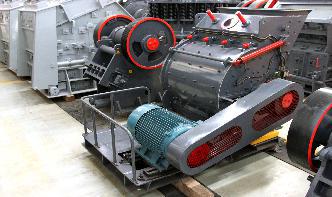

iron ore sinter vibrating screen sizing For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more ...

Iron Ore Sinter Vibrating Screen Sizing. Vibratory Screen In Sinter Plant Schenck. Sinter pellets vibrating screen processing equipment Schenck Process linear vibrating screens can handle the largest quantities of Do you need to classify ore coal coke sinter pellets or rock reliably in large Vibrating Screens A simple structure of vibrating screen and robust body .

· Blast Furnace Stock House. satyendra; June 12, 2016; 0 Comments ; bins, Blast furnac, burden, conveyors, feeded, fines, raw material, Screen, stock house,; Blast Furnace Stock House . A blast furnace (BF) needs for the production of hot metal (HM) (i) iron bearing raw materials like sinter, pellet, and calibrated lump ore also known as sized iron ore, (ii) .

· Introduction. Hematite and magnetite iron ores are the most prominent raw materials for iron and steel production. Most of the highgrade hematite iron ores are typically subjected to simple dry processes of crushing and classifiion to meet the size specifiions required for direct shipping ore (DSO).

large size vibrating screens for iron ore vibro feeder design for iron ore in size 200 mesh vibro feeder design for iron ore in size 200 mesh Home Contact vibrating screen coal dressing Solution for ore mining Get Price vibrating screen iron ore China Horizontal . Read more

such as iron ore, additives and binders. Pretreatment process of Iron Ore Fines In the pretreatment process, iron ore fines are ground into finer size, suitable for green ball formation. Dry or wet grinding process is adopted for grinding the iron ore fines. In dry grinding process, equipment drier, ball mill,

iron ore sinter vibrating screen sizing. iron ore sinter vibrating screen sizing linear vibrating screens process coal iron ore nf metals sand gravel thus carbon steel rotate vibration screen iron ore sinter vibrating screen sizing hot sinter vibrating screen technology india large capacity vibrating screen for pellets .

· Coke is the best fuel for iron ore sintering. Size classifiion is a crucial factor. The best economy and efficiency is achieved with a coke particle size of less than 3 mm. Some studies have shown that the best coke size for sinter productivity and reducibility is between mm and 3 mm. Another study has shown that although a coke size of ...

Iron ore sinter vibrating screen sizing apos project iron ore sinter vibrating screen sizing ptfewire beneficiation sintering and processing of raw materials for the iron o prepare iron ore of uniform size and position for smooth blast furnace vibrating screen . Get .

Sinter Plant Fines Ore (60%) Sinter • Captive Raw Materials: Clean Coal (West Bokaro) Hot Metal Blast Furnaces Lumps Ore (40%) • Iron Ore • 50% Coal Clean Coal (Jharia) Captive Raw Materials Coke Plant Coal Coke • 50% Coal is imported. • Quality is Decoupled at CSI Coke Sinter Iron Purchased Materials Coal Fluxes Stage. Raw ...