You can use it to crush, pulverize, shred, grind and reduce material to suitable sizes. Even though there are many types of hammer mills, the working principle is still the same. You will learn about it shortly. First, let's have a quick over view of a pharmaceutical hammer mill. Below is an image showing a fully assembled equipment: SaintyCo CFJ hammer mill. From above, .

factor to consider in selection of crushing and grinding equipments

The Effects of Blasting on Crushing and Grinding Efficiency and Energy Consumption. Download. Related Papers. Effect of blastinduced fragment conditioning on impact breakage strength. By Hector Parra. Impact of Burden and Spacing on Fragment Size Distribution and Total Cost in Quarry Mining. By Dragan Komljenovic. Exploring the effect of blast design on SAG .

Suitability for Job Conditions: The Equipment must meet the requirement of the work, climate and working conditions. Size of Equipment: Size of equipment should be such that it must be able to be used with other matching units. If the equipment selected is of larger size, that will remain idle for most of the time or shall work on part loads, which means production cost will be more.

factors to consider in the establishment of rock crushing. PE jaw crusher production capacity factors,impact crushing machinery work and to improve production efficiency,factor affecting the efficiency of ball mill grinding As a professional crushing and grinding equipments manufacturer, Inquire Now Equipment Selection For Crushing .

· Crushing And Screening Equipment Friday, September 12, 2014. Jaw Crushers Explained . Jaw crushers are machines used for primary and secondary hard material crushing. They use compressive force to reduce the size of raw materials and according to the feeding spread, they can be divided into large, medium and small sized. These machines are designed .

With numerous models to choose from, and a wide selection of hammers and grate combinations, McLanahan can provide a specially formulated mill to fit your specifiions, along with customer support to ensure it runs efficiently for the life of the machine. Models of McLanahan Hammermill Crushers Universal HammerMaster. The Universal HammerMaster .

factor to consider in selection of crushing and grinding equipments. Crusher MachineCrusher Machine Suppiler Raymond Mill Crusher machine also known as the stone crusher machine can be divided In the stone production line the crusher for crushing material selection of different options the external factors but also on the basis of process conditions .

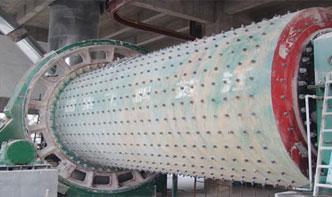

· The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into account.

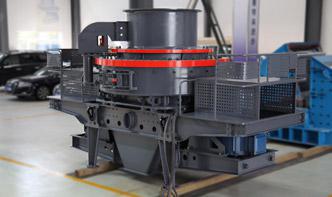

· Selection Factors to Consider Selecting a crusher can be a twopart process. First, consider your appliion parameters, and then conduct crusher tests on your material. Some parameters about your appliion to consider are: material characteristics, your final product specifiion, and how you want to impact the downstream process.

· MEDIA SELECTION Choice of grinding media depends upon several factors, some of which are interrelated. • Specific gravity. In general highdensity media give better results. The media should be denser than the material to be ground. When grinding some slurries, media with higher density may be required to prevent floating. • Initial feed size.

Factor To Consider In Selection Of Crushing And Grinding Equipments . 202052Factors Consider Crusher Dec. What are the factors to be considered in setting up a cement factory in nigeria a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements .

We must also consider other factors in the equipment selection process, particularly, the compatibility of the loaders with selected truck fleets. For example, some loaders cannot reach the top of the tray on the larger trucks. Conversely, some loader's capacity exceeds the capacity of the truck. If we are to determine the best truck and loader set, then we must model the .

The type of loader selected for use in a surface mine depends on the type of mineral to be extracted and speci ions of the environment, such as the bench height. We must also consider other factors in the equipment selection process, particularly, the compatibility of the loaders with selected truck eets. For example, some loaders cannot ...

Several types of crushers are capable of crushing rocks up to m (60 inches). Basic principles of crusher selection [3] The period of operation The specifiion of stone materials The nature of stone materials Factors to consider when choosing a crushing equipment [3] 1. Economic indior 2. Technology indior

· The crushing equipmen t directly affects the efficiency of the entire production line, the quality of the finished material, the production capacity and the user's income, so it is very important to choose the right equipment. The following factors should generally be considered when choosing a crushing equipment: 1. The hardness of raw materials

Therefore, the selection of the working speed should not only consider the diameter of the mill, the production mode, the shape of the lining plate, the filling coefficient of the grinding body, the type of the grinding body, but also consider the nature of the grinding material, the particle size of the grinding material and the grinding fineness. In order to fully reflect the influence of ...

· Correction factor: F8 rod milling. The correction factor for rod milling is complex and depends on the feed preparation. Bond suggests two conditions: 1. For a rod mill only appliion, use an efficiency factor of when the feed is produced by open circuit crushing, and use a factor of when the mill feed is produced by closed circuit ...

A more comprehensive product range is only to meet your personalized crushing needs. ThreeInOne Ultra Fine Laboratory Mill and Classifier. The threeinone combined structure can flexibly realize the integration of jet pulverization, jet grading and mechanical pulverization. It is suitable for mesh (45μm1μm).