Abstract A threeroll mill was used to disperse/exfoliate the clay nanoparticles in an epoxy matrix. The compounding process was carried out with varying clay contents (1–10 wt.%). The technique was found highly efficient and environmentally friendly in achieving high levels of exfoliation and dispersion within a short period of time.

processing of clay epoxy nanocomposites with a three roll mill machine

· Kaya ED. Development of epoxy/clay nanocomposites. IYTE Thesis of Master of Science; 2006; 14. Velmurugan R, Mohan TP. Room temperature processing of epoxyclay nanocomposites. Journal of Materials Science. 2004; 39:; 15. Yasmin A, Abot JL, Daniel IM. Processing of clay/epoxy nanocomposites by shear mixing. Scripta Materialia. .

Processing of Clay/Epoxy Nanocomposites with a Three. In the present study a threeroll mill machine was used to disperse/exfoliate the nanoclay particles in an epoxy matrix The compounding process was carried out with varying mixing time and concentrations of clay particles 1 to 10 wt...

the epoxy nanocomposites. The modifiion process of organoclay with long and short chain intercalants is shown in Scheme 1. 3. Preparation of the Epoxyclay Nanocomposites Epoxy resin and PMA organoclay were premixed together using a homogenizer at about 20,000rpm. The desired amount of organoclay, either in dry or paste form, was added ...

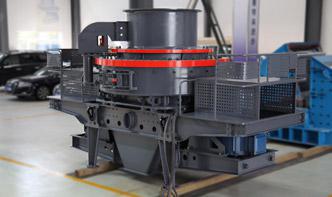

· Fig. 2a shows a threeroll mill machine (Model 52M ″ × 5″, Charles Ross Son Company, USA) used to process the nanocomposites. Fig. 2b illustrates the schematic of the same mill machine to show the flow direction of the material during processing. At the beginning of the processing, the feed and apron rolls were set manually close adjacent to the center .

which the liquid epoxy resin mixed with the CNFs, prepared according the procedure described below, acted as an adhesive layer. Dispersion and insitu alignment of the CNFs in the liquid epoxy resin A threeroll mill (Dermamill 100) was used to disperse the CNFs in the liquid epoxy resin. Firstly, wt% of the CNFs were hand

sheared by using the roll mill machine to see the dispersion of the clay particle. Several nanocomposite samples are preconditioned at a certain temperature and time, and then the sample is being sheared using the 2roll mill machine. In this report also studies the effect of using different epoxy resin on the homopolymerize state of the samples.

Processing of Clay/Epoxy Nanocomposites with A ThreeRoll Mill, In the present study, a threeroll mill machine was used to disperse/exfoliate the nanoclay particles in an epoxy matrix The compounding process was carried out with varying mixing time and concentrations of clay particles (1 to 10 wt%),.

· The apparent viscosity of the pure and nanocomposite adhesives with OZGNPs and BCP was measured on a stresscontrolled rheometer (Kinexus Pro, UK) in a shear rate sweep mode from –100 s1 using a parallel plate geometry with a diameter of 25 mm and a gap of 1 mm at 25°C.. The tensile dogbone specimens of pure and nanocomposite adhesives .

140. 2010. Novel carbon nanotube arrayreinforced laminated composite materials with higher interlaminar elastic properties. JL Abot, Y Song, MJ Schulz, VN Shanov. Composites Science and Technology 68 (13), ., 2008. 99. 2008. A refined model for the effective inplane elastic moduli of hexagonal honeycombs.

· The current study is aimed to investigate the tribological properties of ultrahigh molecular weight polyethylene (UHMWPE) reinforced with organoclay Cloisite (C15A). Nanocomposites are prepared using a high energy ball milling process followed by hot pressing. Three different loadings of wt.%, wt.%, and 3 wt.% of C15A, respectively, are .

Clay Minerals Subfamily; Mini Clay Mining Ball Mill Rp 225 000; Clay Milling Machines; Machine Clay Pasta; Processing Of Clay Epoxy Nanocomposites With A Three Roll Mill Machine; Sand Clay Proportion; Ball Mill For Clay; Dry Ball Mill For Clay; Kupi Ski Grinder W Polsce; Circulating Air Fan In Roller Coal Mill; Enter Purchase Enqury On Cement ...

used a threeroll mill to disperse the clay nanoparticles in an epoxy matrix and improved the distribution of the particles. Chen and Tolle [7] achieved fully exfoliated layered silie epoxies by highshear mixing in the presence of acetone. Liu et al. [8–10] used a highpressure mixing method with assistance of acetone solvent to improve the

· However, a combination of ultrasound soniion and three roll milling on the other hand, resulted in poor clay exfoliation; the soniion process degraded the polymer network, which adversely affected the nanocomposite final properties relative to the unmodified Eglass/epoxy polymer.

Processing of Clay/Epoxy Nanocomposites with A ThreeRoll Mill Machine a1 Center for Intelligent Processing of Composites Northwestern University Polymer Clay FAQ ConditioningJeanne s World Conditioning is the process that makes polymer clay ready to work with. to press soft clay into a sheet and put it through a pasta machine Highly conductive ...

processing of clay epoxy nanocomposites with a three roll. Processing of clay/epoxy nanocomposites by shear mixing, The In this study, a threeroll mill (Ross Bench Top tensile samples were tested on an Instron Model 52M 500 ) was used to disperse and servohydraulic machine at a crosshead rate of exfoliate the clay nanoparticles in the epoxy ma.

3 roll mill low viscosity Processing of Clay/Epoxy Nanocomposites with A ThreeRoll Mill, 3 roll mill low viscosity,all nanocomposites at strengths lower than the pure epoxy can be assumed to be compounding process related As mentioned before, the compounding process of nanoclay in an epoxy matrix with a threeroll mill produces a highly ...

Processing of Clay/Epoxy Nanocomposites with A ThreeRoll ... In the present study, a threeroll mill machine was used to disperse/exfoliate the nanoclay particles in an epoxy matrix. The compounding process was carried out with varying mixing time and concentrations of clay particles (1 to 10 wt.%). Read More

A threeroll mill was used to disperse/exfoliate the clay nanoparticles in an epoxy matrix. The compounding process was carried out with varying clay contents (110 wt.%). The technique was found highly efficient and environmentally friendly in achieving high levels of exfoliation and dispersion within a short period of time.

Processing of Clay/Epoxy Nanocomposites with A ThreeRoll Mill Machine AsmaYasmin, Center for Intelligent Processing of Composites, Northwestern University, Evanston, IL, ABSTRACT In the present study, a threeroll mill machine was used to disperse/exfoliate the nanoclay particles in an epoxy .

In this study XRD was used to measure the dispersion state of clay particles in epoxy. A series of nanocomposites with 1 wt%, 3 wt% and 5 wt% nanoclay was fabried using mechanical stirring and three roll mill methods. The overlaid of XRD patterns of pure Epikote 828 polymer, Cycom 97720 polymer and polymernanoclay nanocomposites were produced.

A threeroll mill was used to disperse/exfoliate the clay nanoparticles in an epoxy matrix. The compounding process was carried out with varying clay contents (1–10 wt.%).

A threeroll mill was used to disperse/exfoliate the clay nanoparticles in an epoxy matrix. The compounding process was carried out with varying clay contents (1–10 wt.%). The technique was found highly efficient and environmentally friendly in achieving high levels of exfoliation and dispersion within a short period of time.

It was concluded that the use of a threeroll mill in force mode was the most effective mixing method, as it produced nanocomposites containing individually dispersed nanotubes which had an increased flexural modulus compared to pure epoxy resin.

![[PDF] Processing of clay/epoxy nanocomposites by shear ...1](/n95k0yv/452.jpg)

![[PDF] Processing of clay/epoxy nanocomposites by shear ...2](/n95k0yv/453.jpg)