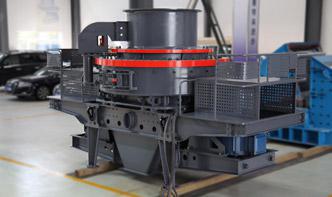

apparatus for crushing the coal charge is on in figure 1. Figure 1 Laboratory model of the unit for coal charge crushing Figure 2 is a schematic diagram of an installation with measuring equipment for carrying out experimental studies, which consist on welded body 1 loed on frame 2, a 3stage rotor 3 with diameters of 150, 200 and 250

basics of coal crushing and screening

screen bars and they reduce by attrition combined with shear and impact reduction. Though attrition consumes more power and exacts heavier wear on hammers and screen bars, it is practical for crushing the less abrasive materials such as pure limestone and coal. Attrition crushing is most useful in the following circumstances:

Crushing. Crushing is often one of the first steps in the production of rock, coal and other minerals, as mined material can consist of boulders that are too big to fit through the processing plant. The type of crusher required depends on the material being reduced. McLanahan specializes in a variety of crushing solutions for reducing minerals ...

basics of coal crushing and screening Basics of coal crushing and screening. The three most basic processes of the coal wash plant are the preparation work before the sorting crushing screening grading the sorting operation and the processing of the selected products At the same time heavy medium coal preparation includes five major processes coal flow .

Basics Of Coal Crushing And Screening. Coal preparation is regarded as the processing of raw coal to yield in the coal cleaning. the four basic operations coal screening and crushing plant has a crusher plant risk assessment crusher mills.

That is, the crushed product is screened and the oversize returned to the crusher for further size reduction while the undersize is accepted as the product. Flow sheets showing two such setups are shown in Figs. and Jaw crushers are installed underground in .

Our screening solutions are ideal for screening, scalping, sizing and dewatering a widerange of appliions to meet the requirements of contractors, miners and quarries. Pilot Crushtec International's machines scalp, screen and dewater millions of tonnes of sand, gravel, topsoil, crushed stone, coal, glass, construction and demolition (CD ...

basics of coal crushing and screening mobile crushing screening and washing plants for the coal and Gulin machine in iron ore processing plant ... Learn More Facts About Coal,, ... basic cleaning

6 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials shown in above figure, a closed circuit crushing system is a means of controlling product top size by screening the product and then returning oversize material to the feed end of the

• Basic J45 Jaw Crusher Coal Crushing and screening project,The new robust J45 jaw crusher is in operation at the Wonderfontein coal crushing and screening project, of 100 000 tons per month. Our machines are also being used at another Glencore Izimbiwa coal crushing project with Zonneblom, of 120 000 tons per month.

Mechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by particle size.. This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recycling.. A method of separating solid particles according to size alone is called screening.

· gold ore crushing plant new zealand . Sep 08, 2018· The specifiion of Vibrating screen mesh/crusher screen mesh/mine screen mesh It is widely used in the large scale stone processing, asphalt mixing plants, coal, We have been the gold supplier of gold ore crushing plant new zealand for 11 years and got certifie of Kenya, Malaysia, East Timor, New .

Mineral Powder equipment . basics crushing,grinding,screening minerals process classifying for . free downloadable pdf files on grinding . »More detailed. Coal Crusher Type Pdf – Stone Crusher Machine. type of crusher used in coke oven plant for crusher coal. . basics in minerals processing handbook pdf; ...

Crushing and Screening Handbook is a dive into the world of rock processing and aggregates production. It goes through the main factors impacting the quality and costs of aggregates, introduces different equipment, and demonstrates various processing methods. After reading the handbook, one should have a clear understanding on aggregates ...

crushing screening flow chart applemart co in . crushing screening flow chart iron ore mining process flow chart Zenith stone crushing Our company is specialized in producing iron ore mining process flow chart the use of more crushing less grinding technology innovative screening and dryTCEQ 40 CFR Part 60 Subpart OOO Flowchart October 3 2003 2 Oct 2003 .

Crushing reduces the overall topsize of the ROM coal so that it can be more easily handled and processed within the CPP. Crushing requirements are an important part of CPP design and there are a number of different types. Screening. Screens in screening plant are used to group process particles into ranges by size. Dewatering screens are used to remove surface water .

crushers by remote controlled hydraulic equipment is recommended but note that this may introduce other hazards such as flying rock chips from impact hammers. Crusher Maintenance A. Hazards during maintenance are many including falls, being caught in moving equipment and being crushed by heavy components. Recently an overseas

· Screening Process; This process involves screening of fine, coarse and wet achieve these process below listed screens are used in coal handling plant. Vibrating Screen; Roller Screen; Crushing Process; This process involves crushing the coal to a size as per requirement of thermal power stations prior to pulverization.

In the initial preparation phase of coal cleaning, the raw coal is unloaded, stored, conveyed, crushed, and classified by screening into coarse and fine coal fractions. The size fractions are then conveyed to their respective cleaning processes. Fine coal processing and coarse coal processing use similar operations and equipment to

The Powerscreen Horizon Range Screens feature horizontal screens ideal for handling high volumes of sticky materials and for the exact, fine sizing demanded in many construction contracts. The Powerscreen Horizon range is ideally suited to appliions such as natural and crushed aggregate, coal, iron ore, recycled concrete and asphalt.

processing plants: (1) sizing, controlled by a crushing and screening process, (2) increasing the heating value of the coal, by removing noncombustible ash and rock, (3) removing or controlling undesirable mineral and chemical components (, sulfur, sodium, and trace elements) In the

The offering includes jaw crushers, impactors, cone crushers, screens and scalpers all designed with your needs in mind. Wheeled offering Our range of wheel mounted semimobile crushing and screening units are complete processing units, many combining both primary and secondary crushing, as well as screening, in one single unit.

· Source: This article is a reproduction of an excerpt of "In the Public Domain" documents held in 911Metallurgy Corp's private library. Scientific Method to Design Crushing Screening Plants. We should consider how the work is done by crushing machines, hammermills and pure impact crushers lift the kinetic energy of the material to a level where .