autogenous mills varies widely and can be as high as three or as low as The literature on the subject of what effect aspect ratio has on grinding mill performance or energy efficiency is almost nonexistent. However, at the design stage of many grinding circuits the subject is often vigorously debated amongst metallurgists.

grinding mill circuit

· These fragments contribute little to the grinding process and their removal results in several benefits in the milling circuit, which include .

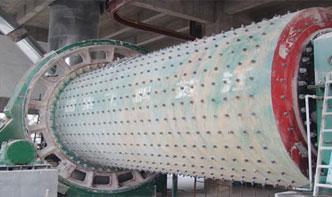

· Grinding mills are size reductions machines that often follow crushers in the processes where finer products are desired after crushing. Different grinding machines are usually named as mills, for example rod mills, ball mills, and attrition mills. Because of the name, verb milling is also been used as a synonym for grinding.

Grinding circuit layout III. GRINDING MODELING The grinding circuit (GC) can be model as two input two output system (TITO). The model in this word was taken from previous work [4]. The two inputs are the pump box water (PBW) and the rod .

· With all the different auxiliary equipment, HPGR total circuit energy usage was still less than 50% of the ball mill circuits. Fines removal from HPGR feed increased grinding efficiency in the ...

Control of grinding mill circuits Whether to achieve a consistent product quality or throughput, a ROM ore milling circuit is a di cult process to control because of nonlinearities, large time delays, unmeasured disturbances, process variables that are di cult to measure, and modelling uncertainties (Coetzee et al., 2010; Hodouin, 2011).

Slurry Flow In Mills GratePulp Lifter Discharge Systems (Part 2) A Novel Approach To The Geometallurgical Modelling Of The Collahuasi Grinding Circuit The Appropriateness Of The Transfer Size In AG And SAG Mill Circuit Design Ag SAG Mill Circuit Grinding Energy Requirement How To Predict It From Small Diamter Drill Core Samples Using The SMC ...

· Predicting the overall specific energy requirement of crushing, high pressure grinding roll and tumbling mill circuits. Minerals Engineering 22, 544549. Davis,, 1919. Fine crushing in ballmills. Transactions of the American .

Grinding Circuits Problem 1 A two stage grinding circuit using a rod mill in open circuit and ball mill in closed circuit with a hydrocyclone classifier is used to grind 100 tons/hr of ore (sp. gr. ). Overflow Hydrocyclone Water Feed Rod mill Ball mill Sump Pump Underflow The circuit is sampled and analysed for 200 mesh material and percent ...

Grinding Optimizer gives you a complete solution for optimizing your entire grinding circuit. Services to stabilize the process, maximize throughput, improve control of particle size, and provide accurate online analyses of variables to optimize your entire grinding circuit.

Since October 2003, the BHP Billiton Cannington mill has operated a grinding circuit consisting of an AG mill, pebble crusher and a Vertimill®which in this paper will be referred to as an AVC circuit. What is unique about this circuit is that it utilizes a Vertimill® for secondary grinding rather than the conventional ball mill.

Grinding operations are very powerhungry, which is another reason to avoid excessive grinding. Grinding circuit. The grinding circuit usually consists of a SAG or AG mill and one or two ball mills. Grinding is continuous and fully integrated with subsequent flotation operations. SAG or AG mills. The crushed products are ground in SAG or AG mills.

The HPGRball mill circuit when grinding to 75 um compared to 160 um used an extra kWh/mt, but for the SABC circuit it only used an extra kWh/mt. The reported SABC circuit power for the 160 μm grind size was based on actual site data.

VTM Grinding Mill Auxiliaries Power: 20 kW VTM Grinding Mill Quantity: 3 Operating Hours per Year 93% . Figure 6: Northland Operating Cost Breakdown Comparison . The operation at Northland commenced at the end of 2012. The flowsheet of the grinding circuit, shown in Figure 7, consisted of 34 ft x 17 ft AG Mills followed by a . €4 €3

Grinding circuits reduce ore to submillimeter sizes, an extremely energy intensive process. As a result, the majority of a plant's energy cost is normally spent here. They are also asset intensive. The high impact, abrasive environment is challenging to equipment making maintenance costs and mill stoppages a big factor.

Modern Cement Grinding Process With Close Circut. Closed Circuit Cement Grinding Mining. The cement mill. Grinding systems are either open circuit or closed circuit In an open circuit system the feed rate of incoming clinker is adjusted to achieve the desired fineness of the product In a closed circuit system coarse particles are separated from the finer product and returned .

Operation and Elements of a ClosedCircuit Ball Mill System . Cement ball mills typically have two grinding chambers. The first chamber is filled with larger diameter grinding media andlined with lifting liners . The first chamber coarsegrinds the feed material and prepares it for the second chamber. The second chamber is the fine grinding ...

· Grinding Mill Circuits – A Survey of Control and Economic Concerns. In: Proceedings of the 17th W orld Congress of the International Federation of Automatic Control, Seoul, Korea, 611 July 2008 ...

Each milling circuit is unique, and as such the goals and most optimal control strategy might differ for individual cases. Process IQ is an expert in implementing control systems for SAG and Ball milling circuits, making use of advanced stabilisation and .

The mills can be operated in open circuit, feeding downstream secondary grinding, or operated in closed circuit as single stage mills generating a finer product size. Single stage SAG Mills are very beneficial in reducing CAPEX for plants with a staged throughput approach.

· 01 The specifics of two grinding ways. Openingcircuit grinding is that, in the grinding operation, the material is fed into the mill and discharged after a grinding, directly into the next mill or the next process.. The advantages of openingcircuit grinding are simple processing flow and lower investment cost. While the disadvantages are lower production .