Grinding Mixing – Ceramic Tiles Manufacturing Process. Raw Materials as per batch composition and chemical composition are grinned in rotating cylindrical ball mills which consists high purity alumina balls as grinding media. Generally two types of grindings are done in ceramics one is Wet grinding and second is dry grinding of raw material ...

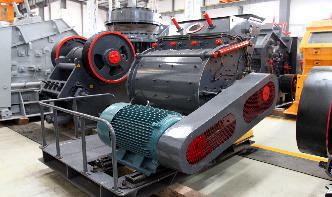

ball mills manufacturing manufacturing process

Module 2 – Ball mills. This module will cover the technology of ball mills used for raw and finish grinding in the cement manufacturing process. * Mechanical description of the different types of mills. * Ball mill grinding equations and dimensioning. * Mill internals, media, liners and diaphragms. * Ventilation, cooling and drying. * Control ...

Important specifiions when selecting grinding mills and pulverizers include, The size of the mill can range from pilot/lab to production,, to 1600 cu. ft. Feed size, material, and hardness of feed must be considered. Output size ranges. Mills can handle dry or wet input, or both. Mills operate in batches or continuously. Appliions

How it Works Crushers Grinding Mills and Pulverizers Ball mills typically use water or other liquid and additives to help reduce friction and provide cooling during the grinding process The feed enters one end of the ball mill and discharges out the other end Ball mills vary greatly in size from large industrial ball mills measuring more than ...

Manufacturing: Process Techniques for the Cosmetic Industry (Harrys Cosmeticology 9th Ed.) ISBN13/EAN: ... Liposome Production Wet SystemsLiquidSolid Systems a. Suspension of Solids b. Milling Equipment c. Colloid Mills d. Ball Mills e. ThreeRoll Mills Filling a. Filling Parameters b. Filling Machines

Ball mill is one of the high fine grinding machine is widely used in industrial production, there are a lot of its type. It is widely used in mineral processing, building materials and chemical industry etc. But do you know how does it work? this paper will .

Ball mill (dry or wet) Usage: Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silie, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable materials.

steel ball manufacturing process wholesale, buy steel ball manufacturing process from 628 steel ball manufacturing process suppliers from China of page 2.

Oct 15, 2020 · In one case, a customer was utilizing a machining process on a simple 3axis machining center. They were having challenges with material tearing when running small ball mills on tight tolerance features. The approach they took was to order electroplated quills of the same size shape as the ball mills to use for the finishing operations.

Lead Cylinder Casting Machine. This system is designed to produce pure lead cylindrical shapes for the Oxide Ball Mill. Lead cylinders are cast on a rotary table fed by a lead melting pot. Fine adjustments of the lead flow from the metering ladle into the moulds allow the control of both cylinder size and weight. DOWNLOAD PDF.

WELCOME TO FACTORY. HENAN ZHENGZHOU MINING MACHINERY CO.,LTD is leading mining equipments manufacturing in the world, who has provided innovative technology and products for mine and energy of over 100 countries and district. It is built in 1956 and loes its factory in XINNGYANG, HENAN, China. Service.

Dec 29, 2016 · Chocolate compound was produced using ball mill refiner, and the effect of agitator shaft speed and refining time on the physical quality parameters (particle size, colour and steadystate rheology) of compound chocolate was .

Ball Mills Manufacturer Ball Mill Working Principle. A ball mill is a type of grinding mill, it is an aggregate for grinding and crushing (grinder) of hard materials that has the same goal as other grinding machinery and crushing mills are used for crushing and mixing of raw materials. While rotating, the grinding media (balls, beads, pulps, etc.) and the raw material .

Manufacturing Advanced Ceramics The process steps in the manufacturing of advanced ceramics such as silicon nitride and sialon, alumina, zirconia and sintered silicon carbide are summarised in the flow diagram below: Raw Material Processes ⇓ Forming Processes ⇓ Sintering ⇓ Diamond Grinding (optional) ⇓ Inspection Each of these stages in the manufacturing .

Our ball mills are perfect for cement plants. Three types of ball Mills we re manufacturing: – 1. Raw materials mill 2. Cement (Clinker) mill 3. Coal mill. Uses / Appliions / Features : Reasonable design and strict manufacture . Strong to grind . Better the ventilating . High fineness . High production capacity and stable to run

Jul 13, 2011 · Advantage: provide reasonable product selection and design,scientific workshop manufacturing arrangements, strict production process,on time delivery Quite simply, the longer the Ball Mill runs, the finer the powder will be. Ultimate particle size depends entirely on how hard the material you're grinding is, and the time how long the Ball Mill ...

Ball Mill, Cement Mill, Grinding Mill, Rotary Kiln, Cement Kiln, Lime Kiln SupplierHenan ZK Corp already has been growing up to a comprehensive company with strong ability of the whole system researching and designing on process technology and equipment manufacturing in the fields of building materials, mining, metallurgy, environmental protection etc.

Ball Mill For Grinding Lime Mortar. Ball Mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes. It works on the principle of impact: size reduction is done by impact as the balls drop from near the top of the shell. It is of welded steel construction, having an