· This system is much more efficient in the grinding ability, but it is much more difficult to line the entire system with wear parts to grind an abrasive material. Ball mill grinding is one method ...

grinding with ball mill system

This combined chocolate ball mill system is composed by one set JM500 / JM1000 Chocolate conching machine, one set QM 1000 Chocolate Ball Mill Machine, Chocolate Pump, Strong Magnetic Filter and Jacketed chocolate pipes. With this chocolate mass grinding system you could easily mill kg chocolate mass within 4 hours.

mathematical model, grinding machining process, cutting experiment of ball end mills, and the calculation for a ball end mill, a ball end mill parametric design system is built by development technology with CATIA 3D modeling software and Visual Basic. With this system obtaining the model of the ball end mill, the simulation is processed in Third

Founded in 1988, Micro Grinding Systems develops and sells industryleading vibratory milling machines. MicroGrinding System's VibroKinetic Mills are extremely fast and very energy efficient. These vibratory grinding machines are versatile and can be operated either wet or dry. Our mills are used in

buy grinding media ball for ball mill in nepal 40mm Ball Media For Ball Mill Introduction DongBang brand 40mm ball media for ball mill can be used for various mines like Iron ore Gold Copper Silver etc By our unique heatment technology we promise you 6365 HRC no breaking Technical datas Appliion 40mm Ball Media For Ball Mill the major grinding media for .

Roller press with Ball mill. Ball Mill. Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years. Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or .

Figure Media motion in the tumbling mill. Grinding Grinding action ... The noload power accounts for all frictional and mechanical losses in the drive system of the mill and can be calculated from No load power D [3 c( Ld L)] ... steel balls in a ball mill, or large lumps of ore in an

Huihe Miningparts Co.,ltd is specialized in design, manufacturing of casting wear parts like grinding balls, ball mill liners, crushers etc. Our marketing offices offers regular onsite technical and aftersales services, to meet our customers milling targets by providing grinding solution, milling system adjustment.

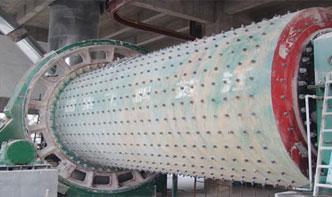

· Figure 1: Slidingabrasion action in a Ball Mill. Figure 2: Cascadingimpact action in a SAG mill. Rubber and composite mill lining systems. In the past, grinding mills were typically lined with cast metal linings of varying steel or iron alloys, and lining system selection was typically driven by level of wear protection and cost.

· Design and simulation of robust ball grinding mill control system Abstract: Aiming at the influence of parameter uncertainty on the control system, two design methods of robust controller are presented to design output feedback controllers, regarding the ball grinding mill system to be the research object. One is the reversedframe normalizing (RFN) method, .

classifiion system in a ball milling circuit. Functional Performance, as developed by McIvor, defines Classifiion System Efficiency, as the net amount of coarse material in the ball mill (McIvor, 1988a). The 'dividing line' between 'coarse' and 'fine' will depend on the grind target of a given circuit, and it is suggested

Mill Type Overview. Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns.; The CenterPeriphery Discharge mill has feed reporting from both ends and the .

This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc. Due to the difference of its slurry discharging method, it is divided to two types: grid type ball mill and overflow type ball mill.

The Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter. The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, to approximately 1/3 of the diameter.

The hammer mill grinding system and the ball and race mill grinding system have been installed. Testing of various coal samples has been underway in the air swept ball mill grinding system. Modifiions to the wet ball mill were delayed while an emergency repair of the sample preparation crusher was made.

· All the possible designs configurations of grinding systems using ball mills can be . pinion with shaft, Pinion Bearing housing, cooling system .. Category: Unegorized. « li gal ba kai bkini mils. impact of crushing and grinding materials on the nutritional value of feed ».

Ball Mill and Classifying Production Line. The world's leading technology, mature technology, stable operation, low maintenance cost, low unit energy consumption, flexible selection of grinding media and liners, highpurity processing, concentrated product size distribution and customizable solutions.

AGICO is a largescale ball mill manufacturer in Henan, China. Founded in 1997, AGICO has grown into a jointstock enterprise integrating independent design, R D, production, and sales. Our ball mill grinders have passed the certifiion of ISO9001:2008 international standard quality management system, wellsold both on the domestic and ...

· Grinding Down to the Nanoscale with Planetary Ball Mills. FRITSCH introduced the Planetary Micro Mill PULVERISETTE 7 premium line in 2006. The production of very fine particle sizes down to the nanometer range was transformed by this highenergy planetary mill by reaching rotational speeds of 1100 rpm. From then on, the PULVERISETTE 7 has ...

· A Ball Mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, and ceramics. A Ball Mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball Mills rotate around a horizontal axis, partially filled with .