Dec 23, 2013 · A ball mill is a type of grinder which consists of a cylinder. It is used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. The cylinder rotates around a horizontal axis. It is partially filled with the grinding medium and .

costs of grinding ball mill

Nov 18, 2008 · Cost Ball mills for wet grinding • To get the price of the ball mill for 2007: 7 13. Summary The Ball Mill is designed to grind materials by turning the cylindrical shell with grinding medium ( steel balls) put in the shell, and .

Mar 08, 2021 · Grinding medium of ball mill The ball is used made of several materials: Grinding medium of ball mill 1 High manganese steel. It has high toughness, good manufacturability and low price. The surface layer of high manganese steel will harden rapidly under the action of great impact or contact.

Compatible grinding jars : 304 stainless steel jars In order to prevent excessive abrasion, the hardness of the grinding jars used and of the grinding balls must be higher than that of the material used. Normally, grinding jars and grinding balls of the same material should be chosen. The tank is not included,only sell the grinding balls

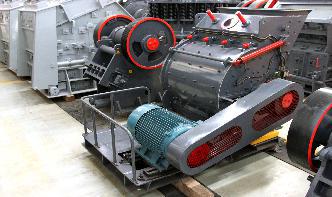

Ball Mill. Ball mill machine is widely applied in the industries, such as cement, silie product, refractory, fertilizer, mineral processing of ferrous and nonferrous metal and glass ceramic, etc. It is mainly used to make dry or wet powder grinding of various ores and other grindable materials. Working Principle Of Ball Mill:

Nov 30, 2015 · 12. ADVANTAGES OF BALL MILL The cost of installation is low. The cost of production is low. It is suitable for materials of all degree of hardness. The grinding medium is cheap. Suitable for both batch and continuous operations. 13.

Ceramics grinding media for Mining and Mineral. Ceramics grinding media for mining and mineral is small size ceramic balls or ceramic beads, used in high intensity stirred mills for fine and ultra fine grinding. The ceramic grinding beads is ideally suited as the cost effecient alternative for High Intensity Mills such as the Glecore IsaMill, Outotec .

SAG mills grind ore by lifting it and a small amount of grinding media and dropping it inside a horizontal mill. Ball mills are smaller and use a higher concentration of iron balls to pummel the ore. The mills can operate in an open grinding circuit, feeding secondary grinding systems, or in a closed circuit generating a fine product.

Dry ball mill is a grinding equipment that uses dry ball milling process to grind materials. Different from the wet ball mill, the dry ball mill does not need to add water when performing the grinding operation, only relying on the impact and crushing effect of the grinding media on the material to grind the material.. The finished material of the dry grinding ball mill is dry .

Jul 09, 2020 · The ball mill liners and grinding media are the largest consumption of wearresistant iron and steel parts with an annual consumption of 2 million tons in China. With the development of China's economic construction, the demand for cement is increasing year by year, and the consumption of wearresistant materials is also increasing correspondingly, which will.

Micron Grinding Mill Factory, Suppliers, Manufacturers from China. All we do is usually connected with our tenet " Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for Micron Grinding Mill, Plastic Powder Pulverzier, Rotor Mill, Ultrafine Grinder, Vertical Roller Mill .

Reliable and effective grinding technology for diverse appliions. With more than 100 years of experience in developing this technology. Outotec has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of appliions.

BALL MILL. Westpro's Ball Mills ensure fine grinding of minerals and ore. Our Ball Mills are engineered to provide the most efficient solution for fine finishing. ADVANTAGES. Liners are less expensive than Rod Mill steel liners. Ideal for fine grinding appliions. Easy grinding media handling. BM58 (5′ Dia. x 8′ Lg) Ball Mill fully ...

Grinding Mills. Fitz Mill grinding unit is used that macerates the whole leaf into a soaplike material. ... easier to control and capital and installation costs are lower, so the number of mills must be decided at the design stage. ... The ball mills are operated at a ball charge volume of 30–32% and % critical speed.

In the everincreasing quest for reduced mineral processing costs and increased throughput tonnages, there has been a worldwide move towards larger and larger mill sizes. As such, FL has supplied some of the world's largest horisontal grinding mills with ball mills up to 28ft in diameter (22MW) and SAG mills up to 40ft in diameter (28 MW).

Jar Mills are available in bench or floor models and have one to six jar capacities in 1, 2 or 3 are used for wet or dry grinding, mixing and blending of ores, chemicals, ceramics, glass, and more. Benchtop Labmill is lightweight and compact and easily adjusts to four sizes of milling jars, 16320oz (–10L).Jars made of HighDensity Polyethylene fit in metal reinforcing .

The cement ball mill is a kind of cement grinding is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical, and electric power has the characteristics of strong adaptability to materials, continuous production, a large crushing ratio, and easy to adjust the fineness of .

SAG is an acronym for semiautogenous grinding. SAG mills are autogenous mills that also use grinding balls like a ball mill. A SAG mill is usually a primary or first stage grinder. SAG mills use a ball charge of 8 to 21%. The largest SAG mill is 42' () in diameter, powered by a 28 MW (38,000 HP) motor.

Jan 27, 2020 · Figure 1: Slidingabrasion action in a Ball Mill. Figure 2: Cascadingimpact action in a SAG mill. Rubber and composite mill lining systems. In the past, grinding mills were typically lined with cast metal linings of varying steel or iron alloys, and lining system selection was typically driven by level of wear protection and cost.

Ball Mills Manufacturer Ball Mill Working Principle. A ball mill is a type of grinding mill, it is an aggregate for grinding and crushing (grinder) of hard materials that has the same goal as other grinding machinery and crushing mills are used for crushing and mixing of raw materials. While rotating, the grinding media (balls, beads, pulps, etc.) and the raw material .

Low Amplitude Wet Mills. Vibratory Grinding Mills Size Reduction Equipment Specifically designed for wet grinding, the low amplitude VibroEnergy Grinding Mills range from ft³ ( liters) to 113 ft³ (3,200 liters) of volume. Wet Grinding Mill Models: M185, .

Cost of 300tph cement grinding mill in india. priceofgrinding mills in india, 201364CostOfGrinding MillsIn Zimbabwe i have recently acquired at a very lowprice,3 almost brand newgrinding millsfrom an associate of m, which is widely used in cement, silie products, new building materials,Ball Mill,Ball mill prices,Ball grinding millof lipu.

Grinding Cost Analysis. According to the relevant data analysis, grinding mill has an impact on grinding cost and performance, accounted for 30% in overall mineral operating costs, accounted for 50% in whole grinding cost, so the grinding mill has a great influence on manufacturing operating rates, total grinding efficiency and total operation cost. . Making a reasonable .