fe nanopowders ball mill in bahrain. nano ball milling price Ball mill Ball Mill Price Ball Mill for Sale Ball mill is the key equipment for re crushing the materials after they are primarily crushed Ball mill is widely used for the dry type or wet type grinding of all kinds of . fe nanopowders 2cball milling. fe nanopowders ball milling High energy ball milling .

fe nanopowders ball milling

Ball Mill Nanoparticle. Retsch PM400 ball mill pump Nanoparticle preparation, For nanoparticle production,, attritor mills and nanoparticles,ball mill size controlling in AfricaWe report on the preparation of magnetite nanoparticles, with size ranging from 12 nm to 20 nm, by high energy ball milling, baje type ball mill;Preparation of NdFeB nanoparticles by surfactant, ball .

Fe Nanopowders Ball Mill. Dielectric properties of BiFeO ceramics obtained from by hot pressing of BFO nanopowders prepared by a mechanochemical synthesis solid solid reaction initiated by milling in high energy ball mills The parameters of the mechanochemical process like milling time shock fre quency and the kinetic energy per hit strongly affects the properties of .

INFLUNCE OF MILLING TIME AND BALLTOPOWDER RATIO OF MECHANICALLY ALLOYED Fe35Mn5Cu ALLOY ON PARTICLE SIZE AND GREEN DENSITY S. SIVASANKARAN*, ABDULAZIZ S. ALABOODI, YASER A. ALSHATAIF, MOHAMMAD SAJID Mechanical Engineering Department, Qassim University, Buraidah 51452, Saudi Arabia .

OF A (AlSiFeCu) ALLOY A THESIS SUBMITTED IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF Bachelor of Technology In Metallurgical and Materials Engineering By KAUSHAL KISHORE SINGH SUDIPTO BHATTACHARJEE Department of Metallurgical and Materials Engineering National Institute of Technology Rourkela 2007 . .

· Nanoparticles of Fe and NdFeB alloy with sizes less than 20 nm were fabried by H. G. Cha et al[118] by a highenergy ball milling process in the presence of surfactant and organic carrier liquid. It was also observed that the Fe and NdFeB alloy nanoparticles were phasetransformed from an amorphous to crystalline state by a heat treatment. This phase .

no reaction during milling (up to 80 h) with ZrO2 cup and balls. Fe and ZrO2 were the major impurities introduced during milling with stainless steel and ZrO2 cups, respectively. The Fe impurity was removed by leaching in 3HCl·HNO3 solution for 4 days. Mean grain size less than 7 nm was achieved at the end of milling. In spite of grain growth, this composite maintained its .

High energy ball milling has been shown to be a promising method for largescale fabriion of rare earthtransition metal nanoparticles. In this work, magnetically hard NdFeB nanopowders with a coercivity in the range of kOe have been produced by surfactantassisted ball milling of nanocrystalline precursor alloys. The nanopowders consisted of .

· The alytic potential of MgO nanopowders was evaluated in preparation of pyrano[4,3‐d]thiazolo[3,2‐a]pyrimidine and chromeno[4,3‐d]thiazolo[3,2‐a]pyrimidines derivatives using the three simple methods including thermal, ultrasonic irradiation, and high‐speed ball milling (HSBM) technique under solvent‐free conditions. All products were successfully .

· Anisotropic Nd 2 Fe 14 B nanoparticles and nanoflakes have been produced by surfactantassisted highenergy ball milling (SAHEBM) of precursor nanocrystalline alloys. A twostage highenergy ball milling was performed to obtain the nanopowders and nanoparticles; first the coarse powders were subjected to a wet milling followed by a wet surfactantassisted .

Milling Figure 2. (a) TEM micrograph of the SmCo5 /Fe colloid obtained by was performed in a planetary ball mill (Fritsch Pulverisette) fieldmilling in the presence of surfactant and (b) the corresponding with the milling vial and balls made of tungsten carbide. For SAED pattern. fieldinduced ball milling, blocks of Nd2 Fe14 B magnets were ...

ball milling (HEBM) from SmCo5 and 5%wt. of Fe powders. The Xray diffraction analysis reveals the hexagonal 1:5 phase as the main one accompanied by the cubic Fe phase and 2:17 rhombohedral as the secondary phase. The content of each detected phase is modified throughout the synthesis duration. A significant decrease in crystallite size with a .

In particular, mechanical attributed contamination by the milling tools (Fe or WC) as well as ambient gas (trace impurities such as O 2, N 2 in rare gases) can be problems for highenergy ball milling. However, using optimized milling speed and milling time may effectively reduce the contamination. Moreover, ductile materials can form a thin coating layer on the milling tools .

Abstract A series of SrTi1−xFexO3−δ (STO or STFO) powders, with x ranging from 0 to, were prepared by selfpropagating hightemperature synthesis (SHS) starting from SrO2, Ti, TiO2 and Fe. A ballmilling (BM) treatment was subsequently carried out for further structure refinement and size reduction. Morphological and microstructural characteristics of both untreated and .

Ferrite Ball Milling Fe Powder. The nanocrystalline inc ferrite ZnFe2O4 powder was synthesied by high energy reactive ball milling RM in a planetary mill. As starting materials a mixture of commercial inc oxide ZnO powder and iron oxide Fe2O3 powder was used. The starting mixture was milled for different periods of time up to 30 h. comparison of the characteristics of .

· Anisotropic Nd 2 Fe 14 B nanoparticles and nanoflakes have been produced by surfactantassisted highenergy ball milling (SAHEBM) of precursor nanocrystalline alloys. A twostage highenergy ball milling was performed to obtain the nanopowders and nanoparticles; first the coarse powders were subjected to a wet milling followed by a wet surfactantassisted .

Highenergy ballmilling of powder mixtures of zincite (ZnO) and iron (αFe) at different weight ratios was performed in air using a planetary ball mill with a stainless steel milling assembly. Structural and microstructural changes during the ballmilling (up to 30 h) were monitored using Xray powder diffraction, field emission scanning electron microscopy (FESEM) and UVVis .

From the literature, it appears that the effect of different microstructure produced by high energy ball milling on biodegradable Febased alloys has not been investigated. The corrosion rate of cold rolled Fe35Mn was higher than the other FeMn alloys [28]. Also Fe 35Mn cytotoxicity was acceptable [29], hence Fe35Mn were chosen for this study. So, the aim of this study is to .

fe nanopowders ball milling ILS COLLECTION. the addition of ductile Fe. 4. CONCLUSIONS Nanopowders of ZrO 2 and Fe were synthesized from Zr and Fe 2 O 3 by highenergy ball milling. The Fe and ZrO 2 powder sizes were 71 nm and 12 nm, respectively. Using the pulsedcurrent activated sintering method, the densifiion of nanostructured FeZrO 2 .

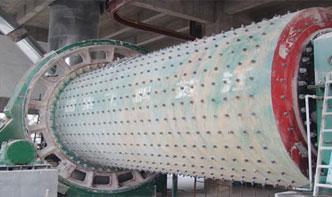

· Ball milling is a method of production of nano materials. This process is used in producing metallic and ceramic nano materials. These mills are equipped with grinding media composed of wolfram carbide or steel. Ball mills rotate around a horizontal axis,partially filled with the material to be ground plus the grinding medium. 6. The balls rotate with high energy inside .