Jun 04, 2006 · The cost of extracting and purifying metals is varied for various reasons, this means that the company might not make profit on the iron ore. Since there is a,relatively, large amount of iron ore it is cheap. This means that the company needs to find a .

extraction of iron from iron ore process

A special purifiion process including Fe precipitation and Zn solvent extraction was implemented. The results showed that after precipitation of iron, Zn extraction of % was obtained with the 2 stages extraction system composed of 30 vol% D2EHPA as extractant. The overall Zn recovery from the ore was %.

Apr 27, 2016 · After iron ore is mined it is send to the blast furnace. Iron is extracted from its ore in a blast furnace. The structure of a blast furnace. Image credit The oxide ores are reduced to iron by removing the oxygen from them. Coke, limestone and iron ore are fed into the top of the furnace. Hot air is forced through tuyeres (openings)

Iron is extracted from iron ore in a huge container called a blast furnace. Iron ores such as haematite contain iron oxide. The oxygen must be removed from the iron oxide to leave the iron behind. Reactions in which oxygen is removed are called reduction reactions.

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite (Fe 3 O 4, % Fe), hematite (Fe 2 O 3, % Fe), goethite (FeO(OH), % Fe), limonite (FeO(OH)·n(H 2 O), 55% Fe) or .

Click here👆to get an answer to your question ️ The manufacture of iron from iron ore involves the process of : Solve Study Textbooks Guides. Join / Login. Question . The manufacture of iron from iron ore involves the process of : A. oxidation. B. reduction. C. fractional distillation. D. electrolysis. E. none of the above. Medium.

We will discuss the extraction of iron from iron ore as an example. Extraction of iron. Iron atoms are found in the compounds FeO, Fe 2 O 3 and Fe 3 O 4 and in rocks like haematite and magnetite. South Africa is the seventh largest producer of iron ore in the world. Iron has been mined in South Africa for thousands of years.

A process for leaching a value metal from a titaniferous ore material comprising the step of leaching the ore material at atmospheric pressure with a lixiviant comprising magnesium chloride and hydrochloric acid is disclosed. Iron and titanium are leached into solution. Iron in the ferric state may be separated from titanium in solution using extraction with alkyl ketone.

Iron Extraction Process ROGESAIron Extraction Process. In the blast furnace process, the first step on the way towards heavy plate, pig iron is produced from iron ore. The composition of the orprocess in the extraction of iron from iro ore

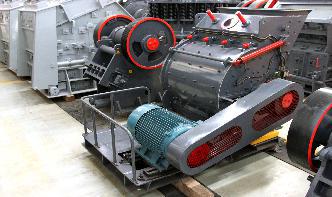

May 15, 2020 · Extraction of Iron. The cast iron is usually extracted from its oxide ore (haematite). This process involves the following steps: 1) Concentration. The ore is crushed in jaw crushers and is broken to small pieces of about 1 inch in size. The crushed ore is concentrated by gravity separation process in which it is washed with water to remove ...

9 Dec 2015 Know How Extraction of Iron from its ore is carried out in the Blast The extraction of metals and its isolation occurs over few major steps . ... Iron Extraction Process In the blast furnace process the first step on the way towards heavy plate pig iron is produced from iron ore The composition of the ore nbsp .

Gold extraction refers to the processes required to extract gold from its may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore.. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting .

Nov 15, 2019 · It is recommended to adopt weak magnetic separation froth flotation process to the extraction of iron ore, namely recycling the iron by the weak magnetic separation process, then recycling the sulfide or apatite through the froth flotation process.

Mar 14, 2014 · Most of the large iron ore mines are mechanized mines. In these mining is done to extract iron ore from surface deposits. In these mines all the operations are mechanized and mining is invariably done through systematic formation of benches by drilling and blasting. Mining process The recovery of material is done from an open pit in the ground.

This concentrated ore is mixed with limestone (CaCO 3) and Coke and fed into the blast furnace from the top. It is in the blast furnace that extraction of iron occurs. The extraction of iron from its ore is a long and subdued process, that helps in separating the useful components from the waste materials such as slag.

May 22, 2009 · The Step by Step Process of Extracting Iron from its Ore using the Blast Furnace with details of Chemical Reactions. Question Answers based on the process of e. SlideShare uses cookies to improve functionality and performance, and to provide you with relevant advertising.

May 11, 2020 · Iron is extracted from iron ore in a huge container called a blast furnace. Iron ores such as haematite contain iron(III) oxide, Fe 2O 3. The oxygen must be removed from the iron(III) oxide in order to leave the iron behind. Reactions in which oxygen is removed are called reduction reactions. Read, more on it here.

The entire process of cobalt and iron extraction was conducted to investigate the influence of cobalt grade and recovery, and the conditions employed were oxidizing roasting temperature of 900 °C, oxidizing roasting time of h, oxygen content of 80%, segregation roasting temperature of 950 °C, segregation roasting time of 75 min, calcium ...

Obtaining metals from this ore is much easier. For example, Haematite ore ( Iron) and Bauxite ore (Aluminium) Sulphide Ores In this particular ore, the metals are present in the sulphide form. Since it is difficult to extract metals from this ore, they are usually converted to oxides with the process of metallurgy.

Mining of iron ore is a highly capital and energyintensive process. Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter ...

oct laterite ore is rich in iron and aluminum and is produced by intensive and .is a flow chart of a process for extracting nickel from laterite ore. Copper Mining Extraction Process Flow Chart This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process.

The process of extraction of iron from its ore is A. decomposition B. oxidation C. reduction D. sublimation Correct Answer: Option C Explanation The Iron is to to be gotten by the removal of oxygen from its ore, and this is called a reduction reaction.

Extraction Of Iron Iron, perhaps the most important element to all civilization is also one of earth's most abundant. Like the majority of metal ores, iron ores are not pure compounds. Rather, most iron ore compounds are polluted with sand, rock and silica. The process of extracting iron involves a number of steps.

Apr 22, 2021 · Extraction of iron is lengthy process which commences from Concentration through calcination roasting. Water and other volatile impurities like sulphur and carbonates are removed by the process of Concentration. The concentrated ore is blended with limestone (CaCO3) and Coke and fed into blast furnace from the top.