Nov 23, 2013 · The bowl mills are further divided into deep bowl or shallow bowl mills. • Impact mill: These are highspeed impact machines that use beater wheels to crush the coal. 12. Ball Tube Mills Tube mills: The tube mills are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder. Due to its shape only, people ...

use of a coal ball mill

Formula For Ball Mill Capacity Coal Power Plant. Ball Mill At Coal Power Plant . improving coal pulverizer performance and reliability. the four most common types of coal pulverizers are balltube mills this type of mill consists of a rotating tube and ballrace mills comprise the majority of coal pulverizers currently in service at power generating facilities operation of the power plant .

In addition, the paper presents energyconsumption ratios, and indies the advantage of this method over mechanical grinding in a planetary ballmill. At optimum conditions, coal comminution at ...

Feb 28, 2022 · Ball mill motor on order for New Century. NEW Century Resources has spent 750,000 on a custombuilt ball mill motor for its Century zinc mine that will become the duty unit when it arrives on site later this year. It will replace the recently repaired motor that was damaged in a January storm. New Century mine processing plant.

The most used coal mills in cement plants are airswept ball mill and vertical roller mill. At present most cement plants use coal as the main fuel in the clinker production process. The standard coal consumed by the new dry process for producing 1 ton of cement clinker is usually between 100 kg and 130 kg and the fuel cost accounts for about .

Sep 17, 2015· 13 Coal Mill Building The coal mill building houses the mill for grinding lumpy coals. This fine ground coal is used for burning in the kiln. 14 Cement Mill and Bag House Clinker, along with additives, is ground in a cement mill. The output of a cement mill is the final product viz. Cement.

ChatNow: https:///Contact: https://: contact About ball mill for coal grinding, ...

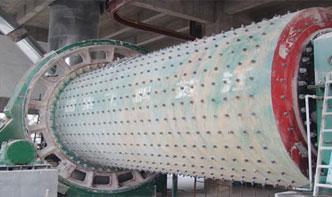

coal ball mill. Coal ball mill is a machine that crushes and grinds the coal briquette into pulverized coal. It is important auxiliary equipment of pulverized coal furnace. During the coal grinding process, the coal is crushed and its superficial area increases continually. To add new superficial area, the bond between solid molecules must be ...

Ball Mill Coal Grinding Coal Grinding Ball Mill Continuous Dry Ball Mill Coal Grinding Ball Mill Buyers In Zimbabwe. 45,300,/ Set. 1 Set (Min. Order) Henan Heavy Industry Science Technology Co., Ltd. CN 7 YRS. ≤1h response time. Contact Supplier.

Aug 09, 2014 · Coal mill has a lot of sorts, such as ball mill, raymond mill, vertical mill, ultrafine mill and so on. Ball mill is most extensively utilized coal mill. It is appropriate in the powder plant, and broadly utilized in powdergenerating production line which includes cement, silie, newkind constructing material, refractory material ...

Ball Mill Noise Control in Cement Grinding Process Ball mill is a kind of grinding equipment in mining field and cement plant It can grind hard stones and materials not greater than 320 MPa such as mineral powder production lines cement production lines .

Coal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing, impacting and grinding. Air swept coal mill is the main equipment in cement plant for both drying and grinding of the powders. Compared with the ordinary ball mill, it has advantages of higher capacity, more convenient .

exploring ball size distribution in coal grinding mills sciencedirect. BSD affects milling top up policy in turn affects rate models can predict BSD for a given top up BSD generally enhances milling rate for uncontaminated coal feed. Tube mills use steel balls as grinding media.

Coal Mills at Klinger Machinery. Klinger Machinery Company, Inc. PO Box 306, Elizabethville Pa.

Ball Tube Coal Mill Direct Level Measurement. a new modelbased approach for power plant tubeball mill jan 25, 2014 the model is verified using onsite measurement data and online test. tubeball mill is another dominant type of coal mill apart from vertical spindle mill in industry.. in order to maintain the coal level inside the mill, the total mass of coal

Our ball mill offers optimum grinding with customized solution that ensures you get maximum grinding efficiency with minimal maintenance. With more than 40 years of expertise and experience in ball mill technology and globally trading operations, we are confident that every product is based on extensive equipment knowledge and guaranteed by a professional service .

Nov 30, 2015 · DEFINITON: • A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering etc. 6. PRINCIPLE: A ball mill works on the principle of impact and attrition. size reduction is done by impact as the balls drop from near the top of the shell.

Jan 27, 2022 · 1 Potential safety hazards in the coal mill system. Spontaneous combustion occurs. The process of cement production determines the need to use a large amount of coal. The use of coal is mostly ...

Coal mill. Energy saving ball mill. Intermittent ball mill. Grid ball mill. Steel ball coal mill. Rod mill. Ceramic Ball mill. Tube Mill. LVRM Vertical Mill. Coal vertical mill. Slag ball mill. Roller Press. Inquiry You can get the price list and we will contact you .

roller mill. GMRC Series coal mill. Output: 5 t/h 70 t/h. Coal vertical mills also called coal mills, which are specialized in superfine grinding of raw coal and bituminous coal ... Compare this product Remove from comparison tool. See the other products. Xinxiang Great Wall Machinery Co., Ltd.

The standard media that we use in our ball milling process are the steel grinding balls, however depending on the specific appliion, we can configure the grinding mill with different media. DOVE supplies various types and sizes of Ball Mill Balls, including; Cast Iron steel Balls, Forged grinding steel balls, High Chrome cast steel bars ...

Air swept Coal Ball Mill is the main equipment in cement plant for both drying and grinding of the powders. Get Price. Coal Mill CHAENG. The coal is grinded into pulverized coal in the coal ball mill mainly by means of three ways: press, strike and grind. Among them, the first way is the most energysaving, and the last one most energyconsuming.

The mill was constructed as development work for the Pole Pick mine by Suckling. The claims was acquired by the Gold Bond Mining Co. in 1936. The Pole Pick claim was worked under lease by another well known miner of the district Fackler in 1940. The mill processed ore by use of a modified ball mill.

Sep 28, 2021 · Steam locomotives excited the senses and Steamtown works to keep their stories alive! You'd feel heat from the firebox, smell hot steam and oil; you'd hear the whistle, feel the ground vibrate, and watch as oneton drive rods turned steel wheels.