VRM WORKING PRINCIPLES. The VRM is a vertically placed large sized machine which is equipped with some rollers used for grinding raw material. It also consists of one table which is rotated by electrical motor raw materials are feeded on the table. Due to centrifugal force on the table, raw material goes below the rollers (a gap between roller table has to be maintain) .

working elements of vertical roller mill

Mar 25, 2015· Hydraulic system vertical roller mill operation 1. The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to .

(Figure 7 shows the working VERTICAL ROLLER MILL TECHNOLOGY AUGUST ... Su Lxp. vertical roller mill detailed analysis and working principle . Vertical Roller Mill Working Principle ... We have a detailed understanding of the major wear problems within the power generation industry and vertical roller... Su Lxp. vertical roller mill working . Vertical roller .

Cement Vertical Roller Mill. The working principle of vertical roller mill 1, the major structure and function Roller is the primary material for rolling mill separator primarily composed of vertical roller mill,roller, disc, compression device, reducer, motor, housing and other elements. Read more

· Vertical Milling Machine. Here the position of the spindle is vertical or perpendicular to the table. This type of machine is adapted for machining grooves, slots, and flat surfaces. Image source: The machine may be of the plain or universal type and has all the movements of the table for a proper setting and feeding the work. The spindle .

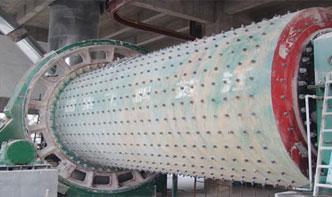

Ball mill vs. vertical mill Operations Structure of a vertical mill Working Process Components Dam Ring Armour Ring Louver Ring Grinding Table Rollers Separators Maintenance Performance on illuminating the structure,working principle and force analysis of vertical roller mill, the finite element analysis of rocker arms is carried out on .

The importance of vertical roller mill in limestone grinding Limestone is one of the ore. It has a long history of mining. It is the main raw material for the manufacture of cement, lime and calcium carbide. It is an indispensable flux limestone in the metallurgical industry. After being ground, highquality limestone is widely used in the manufacture of power plant desulfurizers, concrete ...

working elements of vertical roller mill. Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag. It has the features of simple structure and low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same. Vertical roller mill Wikipedia; Vertical roller mill Wikipedia. Vertical .

Chapter 1220 Geometric Profile Elements General Vertical Alignment Coordination of Vertical and Horizontal Alignments Airport Clearance Railroad Crossings Procedures Documentation References Exhibit 12201 Minimum Length of Sag Vertical Curves Exhibit 12202 Grade Length Exhibit 12203 .

of the work roll bearing and rolling element j. ... force of the work roll bearing to the work roll. Using the rolling mill vertical vibration model in Figure 1, the equations of the dynamic motion are now given by 11 11 2 1 2 11 2 1 2 22 22 1 22 1 23 2 0 ()() ) (b xcxcmx x x kkx x xmxxc xxk x kFx + + −+ + − = + −+ −+ = (6) 3. Simulation and Analysis Using the actual parameters of the ...

· You'll use your CNC milling coordinate system fundamentals everywhere, not just for one particular CNC machine. Even the latest CNC machines are the same at their core: they use an X, Y, and Zaxis to define the coordinate space inside the machine, and a tool (sometimes an endmill, sometimes an extruder, sometimes a laser beam) moves around that space.

A guideway is one of the important elements of the machine tool. The main function of the guideway is to make sure that the cutting tool or machine tool operative element moves along a predetermined path. The machine tool operative element carries a workpiece along with it. The motion is generally circular for boring mills, vertical lathe, etc ...

The vertical roller mill has high energy efficiency and the installation space is smaller compared with tube mills. These days, the vertical roller mills have been widely adopted. A)Structure (1) The rollers are hydraulically pressed against a disc table and the feed is . More. of working of vertical raw mill in cement plant Cement Vertical Roller Mill Great Wall ...

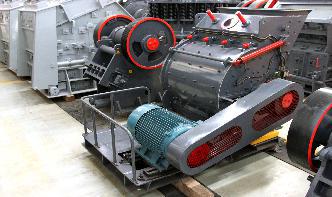

A rolling mill is a complex machine having two or more working rollers, supporting rollers, roll stands, drive motor, reducing gear, flywheel, coupling gear etc. Rollers may be plain or grooved depends upon the shape of rolled product. The metal changes its shape gradually during the period in which it is in contact with the two rollers.

Working Of Vertical Roller Mill. Sep 27, 2021 vertical roller cement mill working principle. Vertical Roller Mill Structure And Working Principle LM series vertical mill is mainly composed of a powder concentrator a roller device an abrasive disk device a pressure device a speed reducer a electric motor and a housing Separtor is a kind of efficient and energy saving .

Vertical. Universal. Ram. Bedtype mill. 14. Machining Centers • Machining center – highly automated machine tool capable of performing multiple machining operations under CNC control. – Automatic tool changer – Pallet shuttles – Automatic workpart positioning • CNC turning center. 15. A CNC millturn center A part. Stock. Turning. Milling. Drilling. A series of operations .

working elements of vertical roller mill. Vertical Roller Mill Working Principle Of Vertical Working Principle Of Vertical Roller Mill It has two pairs of grinding rollers each pair of roller composed of two narrow rollers mounted on the same axis and can rotate at different speeds There are two circular disc slot and roller to the tire shape work pressure in the tank

Vertical Roller Mill,Working Principle Of Vertical Roller Mill. A vertical roller mill is a type of industrial equipment used to crush or grind materials into small particles. These machines consist of a large, heavyduty steel drum that relies on both hydraulic and pneumatic forces to pulverize rock or stone. Get Price. USB1 Vertical roller mill Google Patents. A vertical .

· The milling machine's ram is the vertical overhead part, right under the head and the motor portion. The farthest part of the ram will attach the column of the machine, and the closest one will hold on the head. You can move the ram transversally with a lever it comes with while working in and out. 10. Table with Tslots. The milling machine's table is where all the .

Working Elements Of Vertical Roller Mill. However, despite these benefits, appliions of the vertical roller millCement vertical roller mills, and in comparison with traditional ball The OK mill incorporates unique patented design elements in the roller and table profile that improve operating stability and reliability, and improving the working environment

The Bradley Vertical Blade Classifier (VBC) is designed to separate extremely fine powders direct from any airswept mill. Dynamic classifiers such as the VBC, provide wide flexibility of operation by allowing for instant adjustment of particle separation ranges. How It Works This dynamic classifying technology utilizes vertical oriented blades and a separator rotor to create a vortex, .

· Segmentation pinch roll used in rolling mill line. The pinch roller device is arranged at the foldout flying shear machine outlet. The .

Vertical roller mill F L Co Vertical Roller Mills Manuals peratio manual vertical roller mill wildpeppersf Particle Size and Standard Deviation CPM peratio manual vertical roller mill Product 15 40 Both roller mills and hammermills have been applied to the task of particle size reduction or grinding in feed Adjustment can be manual or remote operated and may feature .