Copper Ore Preparation In The Concentrator. The four major steps in the production of marketable copper are mining concentrating smelting and refining In a few instances however leaching takes the place of concentrating smelting and refining At present although considerable leaching and directsmelting ores are produced the bulk of the copper ore mined is .

copper ore preparation in the concentrator

The Aktogay mine is a large scale, open pit operation similar to Bozshakol. Aktogay commenced production of copper hode from oxide ore in December 2015 and copper in concentrate from sulphide ore in February 2017. In October 2021, the second Aktogay concentrator was opened by the President of the Republic of Kazakhstan.

· Kamoa Copper's Phase 1, Mtpa concentrator plant reached commercial production on 1 st July 2021 after achieving a milling rate in excess of 80% of design capacity and recoveries very close to 70% for a continuous, sevenday period.. Copper production has steadily increased since first production began at the end of May.

· An analysis of energy usage in the production of refined hode copper was made from mining ore to hode copper. In mining copper ore the greatest energy consumers are ore hauling and blasting. Another important factor is the "recovery efficiency" of the metallurgical processes used to extract the copper. The mining and mineral concentrating energies are .

Expansion of the concentrator facilities will increase production of primary sulfide ore and will increase annual production of copper and molybdenum concentrates beginning in 2016. Fluor's Solution Fluor commenced the Cerro Verde Production Unit Expansion feasibility study, engineering, and procurement services from its Vancouver, Canada ...

copper ore was considered, and a modifiion of the ... Sulphuric acid, analytical grade was used to prepare ... scale in the concentrator "Veliki Krivelj". The aim was to get an insight how high is the copper recovery from the ore, liberated from oxide minerals, in the leaching ...

· From 2015 to 2056, this amount is expected to drop to 25Mt of ore being processed each year to produce 60,000t of copper concentrate. Infrastructure facilities and construction. Major construction works carried out at the Bozshakol copper project included the concentrator building, a 200kV power line and a permanent accommodation camp.

· The current copper concentrator is the fourth concentrator to operate at the mine and was built in 1974. It achieves a recovery of 95% copper and in the year 1990/91 treated Mt of ore grading % Cu. The copper ore is crushed underground to 200 mm and is subsequently hoisted to surface in 35 t skips.

A Copper Flotation Flowsheet Because the copper in this type of ore usually assays only plus or minus 1% copper, the porphyry copper operations must be relatively large in order to be commercial. . Open pit mining is generally employed with trucks or train haulage of ore to the nearby concentrator.

jaw Copper Oxide Ore Froth Flotation Concentration . 14/06/2021 Jaw crusher can reach the crushing ratio of 46 and the shape of final product is even It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc The pressure resistance strength is under 200Mpa, that is, suitable for primary crush Jaw .

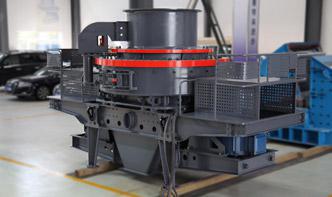

Copper Ore Processing PlantHengcheng offers turnkey solutions for Copper flotation Plant. We are one of the leading project suppliers for Copper flotation Plant and we work closely with our customers to fulfill their specific needs for customized package solution. Specialized in the fabriion of these machines for 25 years and this enables us to

copper ore preparation in the concentrator This process uses a series of physical steps and high temperatures to extract and purify copper from copper sulfide ores in four basic steps 1 froth flotation 2 thickening 3 smelting and 4 electrolysis...

· The Kakula concentrator will be constructed in a phased approach with two 3 Mt/y modules, as the mining operations ramp up to a full orethroughput rate of 6 Mt/y. Kakula is expected to produce a veryhighgrade copper concentrate in excess of 55% copper, with extremely low arsenic levels, according to Ivanhoe.

· Chart 3: Growth in contained copper in ore stockpiles at the Kakula and Kansoko mines – May 2020 to September 2021. The Kakula Mine, concentrator plants and main ore stockpiles at Kakula's northern declines (in red circle). The blended stockpiles currently contain approximately million tonnes grading % copper.

· Copper production from the first Kamoa Copper's two phases projected to exceed 450,000 tonnes per year by Q2 2023, positioning Kamoa .