Kenyan Iron Ore: Mining and prospects of Processing Maranga, S M and Bett, Alvin Kiprono and Ndeto, Kyalo and Bett, Gilbert (2013) Kenyan Iron Ore: Mining and prospects of Processing. In: Proceeding of the International Conference on Science and Technology of Ironmaking and Steelmaking, December 1618, 2013, CSIRNML Jamshedpur.

mining of iron ore process

Dry processing at Vale. In the last 10 years, Vale invested almost R66 billion in facilities and development of technologies for the dry iron ore processing production. Today, most of our iron ore production (about 60%) is through dry processing. The natural moisture processing is used at Carajás and Serra Leste mines, at S11D Eliezer Batista ...

of the processed ore shipped to the iron and steel industry is in the form of pellets. Other forms of processed ore include sinter and briquettes. The average iron content of pellets is 63 percent. Process Description25,41 Processing of taconite consists of crushing and grinding the ore to liberate ironbearing particles, concentrating the ore by separating the particles from the ...

· Iron ore consists of oxygen and iron atoms bonded together into molecules. To create pure iron, one must deoxygenate the ore, leaving only iron atoms behind, which is the essence of the refining process. To purify and strengthen iron, materials like coke are mixed in with it to remove oxygen. To coax the oxygen atoms away from the ore requires ...

· Christmas Creek iron ore processing facility in Western Australia (Credit: Fortescue Metals Group) Iron ore producing companies supply a vital component of modern industry, with iron ore used across the world primarily as an ingredient in steel manufacturing. The metallic ores, which can vary in colour from dark grey and bright yellow, to purples and .

· Cheap, openpit mining methods were used, and good extractions were obtained when grinding to only 3 mesh. These, among other factors, made for extremely lowcost operation. The 596,482 tons milled yielded per ton at a total cost of per ton of which was milling cost.

Energy consumption, including the energy required for the mining and processing of iron ores. Such processes as blasting, ripping out, loading, and transporting ore to treatment plants, as well as the treatment and transportation of the product to the market, consume significant amounts of energy (not to mention the consumption of the primary steel industry). Units of MJ/ton of ore .

OF MINING, QUARRYING AND OREPROCESSING WASTE IN THE EUROPEAN UNION Study made for DG Environment, European Commission Coordination by P. Charbonnier December 2001 BRGM/RP50319FR. BRGM/RP50319F 3 Key words: mining waste, mines, quarry, exploitation, ore processing, environment, impact, inventory, legislation, simplified risk .

Iron ore is found in nature in the form of rocks, mixed with other elements. By means of various industrial processes incorporating cuttingedge technology, iron ore is processed and then sold to steel companies. The iron ore produced by Vale can .

We are a leading North American producer and exporter of premium iron ore pellets and highgrade concentrate. Our operations include a mine with five operational pits, a concentrator and a pelletizing plant loed near Labrador City and the whollyowned 418 km railroad, the Quebec North Shore and Labrador Railway (QNSL), that links our Labrador operations to Company .

Differences in ore composition and presence of iron, silicon and titanium impurities influence their subsequent processing. 90% of the world's bauxite reserves are concentrated in tropical and sub tropical regions. Large blanket deposits are found in West Africa, Australia, South America and India as flat layers lying near the surface, extending over an area that can cover many square ...

· Bog iron is much easier to smelt because it contains fewer impurities than iron ore in rock deposits, but the quantity of iron available from bog iron is relatively low (although actually renewable, unlike mines; a bog can be harvested for iron again after a few decades as the processes which produce the bog iron continue). Because of its low output, bog iron .

Mining Of Iron Ores Ispatguru . Mar 14 The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state It consists of several distinct steps The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent .

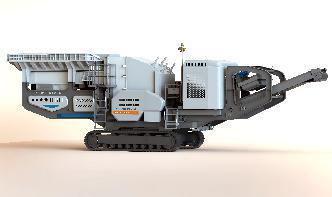

· The process of mining lowgrade iron ore, or taconite, requires massive resources. Heavy industrial mining equipment, expansive mines, and a skilled labor pool are all required. The equipment used includes diamondbit rotary drills, hydraulic shovels and loaders, water wagons, production trucks and heavyduty conveyors. National Steel Pellet Company's plant is .

· After adaptation in the state of Minas Gerais' iron ore operations, the sandy material, previously disposed in piles and dams, is now being processed and transformed into a product, following the same quality controls used in the production of iron ore. This year, around 250,000 t of sand has been processed and destined for sale or donation to be used in .

Iron Ore Process Mining. Iron Mining Process. From blasting to crushing to separation than 85 of the iron mined in the United States is mined in northeastern Minnesota to make our nations steel. Blasting Taconite is a very hard rock. Using explosives, the taconite is blasted into small pieces. The iron ore is separated from the taconite using magnetism. The Worlds Biggest .

· Skarn Associates is pleased to announce the first release of its Carbon Emission Curves for the mining industry. These curves and underlying minebymine data are available for iron ore, copper ...

LOCATION FOR THE IRON ORE MINING AND PROCESSING PLANT . The best project site for the Iron ore mining and processing in Balochistan is the iron ore reserves sites of the province especially, Dilband which possesses Iron ore of 200 million tons. By producing iron near the mining site will also reduce the transportation cost of carrying raw material to other cities .

Iron processing processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mprocessing mining of irone ore