grinding mills (SAG and/or Ball mills) to ensure sufficient solidliquid contact during the digestion phase, which improves alumina extraction efficiency. A solution of hot concentrated sodium hydroxide (NaOH, caustic soda) liquor, taken from the recycled caustic liquor circuit, is added to the bauxite during grinding to produce a slurry.

ball mill in power plant pdf

12. Ball MillBall Weight Surface Area 97 13. Ball Mill Charge Volume 98 14. Useful Data for Grinding Mill Study 99 15. Ball Mill Charging 99 16. BIS Specifiion of Additives 102 17. BIS Specifiions for various 103 Cements 18. Thermo Physical Properties of Different Insulating Materials 107 19. Pollution Standards for Stack, Ambient ...

Figure 5: Typical Power/Load curve Figure 6: Mill Optimisation Control Strategy. MillSTAR. THROUGHPUT OPTIMISATION. SEGREGATED ORE FEED CONTROL (Feed Ratio Optimisation) On milling plants fed by a segregated feed supply, such as a stockpile, the varying size and hardness of the mill feed material affects the residence time in the mill and the ...

TECHNOLOGY REVIEW NO. 29 DEC. 2010 58 Pelletizing Process Shinichi YAMAGUCHI*1, Takeshi FUJII *1, Norihito YAMAMOTO, Tsutomu NOMURA*2 *1 Plant Engineering Department, Iron Unit Division, Natural Resources Engineering Business, *2 Technology Process Engineering Department, Iron Unit Division, Natural Resources .

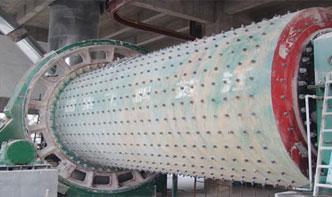

· A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size.

At some gypsum plants, drying, grinding, and calcining are performed in heated impact mills. In these mills hot gas contacts gypsum as it is ground. The gas dries and calcines the ore and then conveys the stucco to a product cyclone for collection. The use of heated impact mills eliminates the need for rotary dryers, calciners, and roller mills.

In general, ball mills can be operated either wet or dry and are capable of producing products in the order of 100 μm. This represents reduction ratios of as great as 100. Very large tonnages can be ground with these ball mills because they are very effective material handling devices. Ball mills are rated by power rather than capacity.

Hullets own bagasse power generating facilities at Maidstone, Amatikulu and Flexiton mills. The boiler plants consists of standard thermal cycle steam boilers with turbo alternators operating in back pressure mode. The exhaust steam is then used for processing of sugar. The installed capacity for the Tongaat generating plants is 72MW.

ball mills. Loesche , Germany, has ... use of a mill plant requires consideration of the following: • high production rates in the presence of potential limitations in: – mill table power – mill differential pressure via the mill fan – external recirculation system via bucket elevator or other conveyors

ausra pdfs design 240 mw solar thermal power plant . ausra pdfs design 240 mw solar thermal power plant mills 2004 Nowadays, parabolic trough solar thermal plants are prevalent around the world. In different areas concerning the amount of solar radiation, their standard size is approximately between 20 and 100 MWe.

power plants could especially benefit nuclear plants, which are costly to build. Policies that reduce the cost of fossil fuels could benefit natural gas plants, which are inexpensive to build but rely on an expensive fuel. The report provides projections .

Coal Handling Plant In Thermal Power Plant. The initial process in coal based thermal power plant is coal Function of coal Handling Plant in thermal power .. Read More. Ash Handling System In Thermal Power Plant. In thermal power plants, coal is used as a fuel for generating electricity. After burning of coal, 40 % of ..

For example, if you had a boring mill that was operating at 100 kW and the apparent power consumed was 125 kVA, you would divide 100 by 125 and come up with a power factor of 0 .80 . Figure 3. kVA power Figure 4. Power triangle Note: A right power triangle is often used to illustrate the relationship between kW, kVAR and kVA . PF = = cosine θ

mill power multiplied by the CSE. Therefore: Circuit production rate of new fine material (t/h) = Total mill power (kW) x CSE (%) x Mill grinding rate of coarse material (t/kWh) (2) Production rate, mill power and CSE can be measured during a plant circuit survey. The mill grinding rate of coarse material is then calculated.

This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc. Due to the difference of its slurry discharging method, it is divided to two types: grid type ball mill and overflow type ball mill.

A Review on the Extraction Methods Use in Medicinal Plants, Principle, Strength and Limitation.

BALL TUBE MILL COAL FEED COARSE WET COAL FEEDER PRIMARY AIR CRUSHER. DRYER BYPASS DAMPER Figure 4 Ball Tube Mill Pulverizing System 8. Operate at system primary air temperatures below those historically used as normal. The trend is toward classifier outlet temperatures of 125 OF away from 150 160 OF.

Walks the walk, talks the torque. Designed to deliver exceptional levels of performance and value, David Brown Santasalo ball mill drives are optimised for primary and secondary grinding appliions. Extensively field tested and proven in harsh cement appliions, our mill drive gearboxes cover all grinding appliions up to 10 MW per drive ...

· Pulverizing Plant • In modern thermal power plant, coal is pulverized • ground to dust like size and carried to the furnace in a stream of hot air. • Pulverizing is a means of exposing a large surface area to the action of oxygen and consequently helping combustion. • Pulverizing mills are further classified as: 1. Contact mill 2. Ball ...

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each appliion. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with .

1. Hammer Mills 2. Rolling Compression Mills a. Bowl Mills b. Roller Mills 3. Attrition Mills 4. Tumbling Mills a. Rod Mills b. Ball Mill; Pebble Mill c. Tube Mills; Compartment Mills A primary crusher operates on run of mine material accepting anything that comes from the mine face and breaking into 150250 mm (610 in).

BIHAR STATE POWER TRANSMISSION COMPANY LIMITED MANUFACTURING QUALITY PLAN HARDWARE FITTINGS Company name and address CUSTOMER : BSPTCL Vendor Code : Item : Hardware Fittings, Conductor Earthwire Accessories P. No. 028 Rev. No. 00 Date : Valid From: Valid Up to: Till Revision Sr. No. Components / .

GUJARAT TECHNOLOGICAL UNIVERSITY BRANCH NAME: Mechanical Engineering SUBJECT NAME: Power Plant Engineering SUBJECT CODE: 7th SEMESTER Type of course: Applied Engineering Prerequisite: Engineering Thermodynamics, Fluid Mechanics, Heat Transfer Rationale: The course is designed to give fundamental knowledge .