02/06/2017 · Hammer mill Impact mills are similar in construction and principal to HSI and VSI crushers. Impact mills are used to pulverize feed material by impact against a surface or a bed of feed material. The feed material may be propelled by gravity or by a rotating impeller or rotor. The impellers or rotors can be vertically or horizontally orientated.

hammer mill vs bowl mill

07/07/2017 · Hammer mill configuration. The three basic types of hammer designs are: The stirrup or LFS hammer, the swing bar hammer and the rigid bar hammer. The stirrup hammer has the most surface area and is used at high speeds to produce the finest particle sizes. The swing bar hammer is used on materials that do not respond well to impact.

Mechanical milling aims to reduce the particle sizes of material by physically breaking the structure of a material by overcoming the materials own interior bonding forces. Types of mechanical mills include hammer mills, ball mills, pin mills and roller mills.

08/03/2018 · The Schutte Hammermill Mini Mills offer the same operational capability of larger size reduction equipment at the fraction of the price. The Mini Mill is available in three sizes, the smaller Mini Mill4 can process between 50 and 100 lbs/hour of various materials. This completely portable unit plugs into a standard wall outlet.

1. Hammer Mills 2. Rolling Compression Mills a. Bowl Mills b. Roller Mills 3. Attrition Mills 4. Tumbling Mills a. Rod Mills b. Ball Mill; Pebble Mill c. Tube Mills; Compartment Mills A primary crusher operates on run of mine material accepting anything that comes from the mine face and breaking into 150250 mm (610 in).

iron, low power consumption, easy maintenance, wide range output, quiet operation. The basic features of Bowl Mill (Puveriser) supplied by BHEL are: Medium speed range of 40 to 60 rpm. Motor speed range of 600 to 1000 rpm. Speed reduction by two method : 1) single stage worm worm wheel set 2)Planetary Gear Box Input coal size is 25 mm while output is 6575 micron.

07/12/2021 · Cone Crushers consist of a bowl liner, a mantle, both main shaft and frame, compression, and an eccentric inner and outer bearing. Essentially, material is reduced in size by squeezing the material until it breaks. Specifically, the material is compressed between a moving piece of steel, the mantle, and a stationary piece of steel, the bowl liner.

Hammer Mill Vs Grinder. Roller mill vs hammer mill when grinding processors decide which mill roller or hammer is best suited for their grinding bulletin also contains information pertaining to the general design and operating parameters of roller mills and hammermills and an explanation of how these mills reduce ingredient particle sie.

Hammer Mill Vs Bowl Mill,hammer mill vs bowl mill bowl hammerhammer milldan grinder the free encyclopedia a hammermill is a mill More Info Live Chat milling efficiency in distillery operations distillery milling efficiency hammer mills use rectangular pieces of hardened steel attached to a shaft rotating at high speed inside the milling chamber.

hammer mill vs bowl mill. ball mill, hammer mill, roller mill machine, manufacturer of high . 0 019 dia micro carbide ball mill 2 flute ball nose end mills · 0 1 mill itu berapa meter, 100 ... Hammer Mills | Product Brochures | Schutte Buffalo Hammermill. Brochures include: hammer mills, grinders, crushers, and lumpbreakers. Connect with us ...

Occasionally, the mill is preceded by a hotairswept hammer mill which does most of the drying and produces millimetresized feed for the mill. Ball mills are rather inefficient, and typically require 10–20 kW·h of electric power to make a tonne of rawmix. The Aerofall mill is sometimes used for pregrinding large wet feeds.

Seventh step: milling Mill the dried cassava mash to produce flour. Milling can be done using a hammer mill (village posho mill). Eighth step: sifting Using a simple homemade sieve, sift the milled flour to remove fibrous materials and any lumps. This is important to obtain highquality freeflowing flour, free of fibre

09/07/2007 · You have to weigh up the pros and cons of hammer milling versus roller milling. By the sounds of things you are looking to have a constant particle size on your grounded corn or wheat. For this rolle mills will suit your appliion better, as the gap in the roller mill will be the particle size you require.

Bowl mill system The typical Raymond® bowl mill system is designed to simultaneously dry, pulverize, and classify solid fuels to 95% passing 200 mesh (<5%R75μ) with a wide range of capacities from 24 to 150 stph. Raymond® Bowl Mills provide the following performance features: Wide range of capacities – base capacities from 8 to 150 tph.

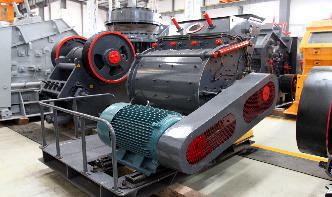

impactor vs hammer mill. Hammer crusher is divided into single rotor and double rotor. The main body is composed of box, rotor, hammer head, impact lining plate, sieve plate, etc. it can directly crush the material with the maximum particle size of mm to 25mm or below.

Hammer mills are often used for generalpurpose grinding and the finished product particle size ranges from millimeters to tens of microns. The jet mill is primarily used for superfine grinding appliions and creates particles sizes down to a few microns. Understanding the fundamentals of each mill's respective grinding mechanisms ...

The SDx ™ Series affords the ability to easily transfer between productionscale Quadro ® Comil ®, FlexSift security screening, and Fitzpatrick hammer to SMARTdetect ™ technology, head recognition and RPM range adjustments are made automatically, enabling you to change heads in seconds, thereby improving production efficiency.. Rest assured that .

19/09/2017 · A milled face, also called checkered face or waffle face, is a pattern on the striking face of the hammer. Different brands use different patterns, but the idea is to provide a bit of extra gripping surface to ch and sink nails. Patterns vary from a mellow set of concentric rings, which some may not consider a true milled face, to seriously ...

Hammer Mill Vs Bowl Mill. Hammer Mill Vs Bowl Mill The difference between a roller mill and a hammer mill is a hammer mill uses rotating hammers to pound grain through a screen and it requires a lot of horsepower you get a lot of powder with larger deviation from the Learn More . Super Bowl 2018 : Doritos

29/08/2017 · Furthermore, roller mills' specific energy consumption is lower. Thacker (2006) found no effect of mill type hammer vs roller on performance of pigs but that study found roller mills had lower energy consumption, more accurate control of particle size, and quieter operation. "Vukmirović et al. (2016b) determined that specific energy ...

Hammer mills use large rotating drums with protruding metal bars (, hammers) that impact the material at high veloc ity to shatter and tear material particles. Typically, the metal bars swing freely from the drum, but fixed hammers are also common in hammer mill designs. Hammer mills are recognized as technology capable

Large hammer mills used in automobile shredders may be driven by diesel or electric motors ranging from 2000 to over 5000 horsepower ( ). The screenless hammer mill uses air flow to separate small particles from larger ones. It is designed to be more reliable, and is also claimed to be much cheaper and more energy efficient than ...

Hammer Mills without Internal Air Classifiers, 2041 ... Likewise the area under the Roller diagram of weight percent per micron against log of diameter . Nov 17, 2012 . Classifiion The circulating air is also used to classify the . Ball tube Bowl Hammer mill Ball race mill millDominating Attrition Crushing Impactprinciple; 11. .