Commercial concrete crusher rental in md jaw crushing machine hazards and consequences working of feeders in crushers jaw crusher design data and requirements crusher supplier in riyadh internal diagram of a rock crusher spesifikasi coal crusher 500 ton h mobile crushing plan concrete in india por le rock crusher georgia crusher."A key component in maximizing .

working of impact crushers

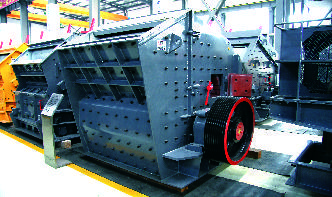

Impact crushers they involve the use of impact rather than pressure to impact crusher working principle Impact Crusher Working Principle impact crusher working principle. impact crusher is widely used in various kinds of hard and brittle materials such as rock, abrasive, refractory, cement clinker, quartz stone, iron ore, concrete aggregate, etc. sand .

Impact Crushers. Finlay offer a comprehensive range of Mobile Impact Crushers that excel in quarrying, mining, demolition and recycling appliions. Combined with our after sales support the Finlay range of Impact Crushers can take your operation to the next level.

crushed waste can be taken from the bottom part. The removed waste is in the shape of the bin and holds together as a single solid model and is easy to transport. 3. OPERATING MECHANISM This crusher works on the simple mechanism called crank and slotted lever mechanism. When the motor is excited

Austenitic manganese steel – steel alloyed with more than 10% manganese – is workhardening. That means that high impacts – like those in a crushing chamber for example – cause the formation of a extremely hard surface layer that is two to three times harder than the rest of the alloy If impacted enough, this results in a hard exterior layer backed by a softer core.

· working principle of impact crusher pizemballfrcrushers principle working ipesmnetin. Impact crusher Working principle of impact crusher The working principle of impact crusher The so called impact crushing refers to the object in the free state by the strike force and along its natural cracks bedding joints and other weak parts of the selective .

Impact crushers (also known as impactors or horizontal shaft impactors) can be used in primary, secondary, or tertiary appliions. They use inertia of the blowbars fitted to the rotor to fracture the material, resulting in a high reduction ratio.

Impact Crusher Working Principle. Impact crusher of concrete crushing form of liberal crushing, rebound crushing, and milling crushing. When crushing material, material dangling dealt hammer blow. If the particle size is small, the impact approximated through the particle's centre of gravity, the item is along the tangent direction free. blake ...

UH440i Mobile Cone Crusher; Gyratory Cone; Impact Crusher; QI442 Impact Crusher; QI341 Impact Crusher; Heavy Range; Roll Sizer; MiniCrushers; Wheeled Units; UI310+ Wheeled Impact Crusher; Screeners. Scalper; QE141 Mobile Scalper; QE241 Mobile Scalper; QE342 Mobile Scalper; QE441 ...

The QI240 utilises market leading impactor technology enabling the development of a fully mobile, compact impact crusher designed to either work in a primary or secondary capacity either independently or in conjunction with other members of the product line, in order to produce the highest quality materials.

impact crusher working principle mineral starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the . working principle of jaw crushers . working principle of jaw crushers Aggregate Impact Crushing Machines working principle theory of vibrating screens .

· Horizontal Shaft Impact crusher (HSI) Impact crusher working animation The working principle of impact crusher is that the spinning rotor under the driving of the motor can genetate strong impact force which make blow bars crush stone material into small pieces. Then the crushed material would be thrown by hammers towards, which makes another crushing .

· Hammer mill Impact mills are similar in construction and principal to HSI and VSI crushers. Impact mills are used to pulverize feed material by impact against a surface or a bed of feed material. The feed material may be propelled by gravity or by a rotating impeller or rotor. The impellers or rotors can be vertically or horizontally orientated.

Highspeed cone crushers in the secondary position are perfect for cubic aggregate when paired with a primary jaw or impact crusher. For an abrasive, tough material like an igneous rock, a primary jaw/secondary cone setup works well, while jaw/impact and impact/cone crusher sets work well for the softer stones.

Consequences Quarry Crusher. Quarry crusher working process of quarry crusher,quarry crusher quarry crusher equipment: common varieties quarry crusher have jaw crusher,hammer crusher, impact crusher, cone crusher, ball mill, sand making machine, ultrafine grinding mill, the user can according to the hardness of the broken material, maximum feed size, and .