Apr 23, 2018 · Planetary ball mill maintenance. Apr 23, 2018. Ultrafine powder equipment Planetary ball mill has maintained a hot market since its inception. From Harbin to Hainan, and from Xinjiang to Shanghai, laboratories, research institutes, and corporations that require powder grinding equipment in various regions are full of planets.

turning a ball mill for maintenance

OEM visual inspection of the mill with temperature, pressure, and flow readings. Catch cracks, drivetrain misalignment, oil contamination, vibrations, missing bolts, equipment condition and more. Performed with 1 shift with mill running and 1 shift with mill stopped. Historical data helps predict mill component performance over time.

Scheduled offline maintenance or failure of one of the Ball Mills (or its ancillary equipment) causes a 50% loss of milling production. Most of the maintenance results from timedependent failure mechanisms ( wear, corrosion or fouling). The crushing circuit has a mean running time to failure of 6 months.

May 29, 2013 · Ball mill operation, ball mill maintenance. A ball mill grinds material by rotating a cylinder with steel grinding balls/ceramic balls causing the balls to fall back into the cylinder and onto the material to ..

Jul 30, 2009 · principle of ball mill,grinders and crushers Thursday, July 30, 2009. ... the connection of higher turning speed and stroke makes the rated power and passing capacity improved greatly and the crushing ratio and capacity increased. 2. Less spare part consuming and low operation cost. ... Easy maintenance and operation.

Maintenance Procedures Of Ball Mill . ball mill operation procedure, ball mill operation and ... second, ball mill maintenance procedures stone crusher . 1 in the event you drive, check the good ... Ball mill repair and maintenance Mining And Crushing . Ball mill repair and maintenance: 2. Ball mill maintenance.

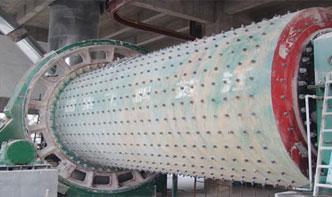

Ball Mill Principles Ball mills, sometimes referred to as pebble mills or tumbling mills, are milling machines that take the form of cylindrical vessels containing balls mounted on a metallic frame that can revolve around its longitudinal axis. Depending on the feed and mill size, balls with varying diameters occupy 30 50 % of the mill volume.

Ball Mill Picture Designball Mill Picture Download; Royal Master Values; Centre To Centre Ten Tons Grinding Machine; Turning A Ball Mill For Maintenance Coal Russian; Vacancy Coal Kerja; Table Grinder Sowbhagya; 1830 7000 Cement Ball Mill; Ball Mill Supplier In Mexi Scmcrusher; Quarz Ball Mills In Ap; Poi Milling Machine; Ball Milling Subsidiary

A planetary ball mill includes: a revolution turning arm turned about a revolution shaft rotated by a driving force; mill pots each supported on the revolution turning arm so as to be rotated about a rotation shaft inclined from the vertical direction toward the side of the revolution shaft; and an outer circumferential pot receiver which is disposed fixedly on the upper side of the revolution ...

Handbook for Ball Mill Grinding: Description, Maintenance, Practice, Controls of Ball Mills to be Used for Grinding Industrial Products as ... Romano Ferrari. Faenza Editrice, 1985. 0 Reviews. What people are saying Write a review. We haven't found any reviews in the usual places.

Oct 29, 2009 · Oct. 29, 2009 PRLog When you or your company use the ball mill, the follow is should be noticed: operators must be qualified with the required technical knowledge, receive technical training and fully understand the operating principle, performance an .

Ball Mill machine is composed by feeding part, discharging part, turning part and driving part (reducer, small driving gear, electric motor and electric control). The quill shaft adopts cast steel part and the liner is detachable. The turning gearwheel adopts casting hobbling process and the drum is equipped with wearresistant liner, which has ...

Cement ball mills manuals schilderijoppostzegeln. Ball Mill Operation And Maintenance Manual Pdf itslange ball mill maintenance YouTube 8 Feb 2014 operation and maintenance manual ball mill Find the Right and the Top operation and maintenance manual ball mill Learn More About ball mill operation and maintenancerelated information:crusher, grinding machine used .

SAG BALL Mill Maintenance SAG Mill make use of steels balls included with some large hard rocks for grinding. These mill utilize the balls in making the large fragments of materials broken into pieces and ball mills are used primary for single stage fine grinding, regrinding, and as the second state in two stage grinding circuits.

Medium or largesize mills are equipped with a lowspeed transmission device to supply cylindrical rotational speed of r/min for barring, maintenance and charge loosening. A largesize mill is equipped with a hydraulic lifting jack that jacks the rotary part for maintenance without spending on a bridge crane.

The cement ball mill is a kind of cement grinding is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical, and electric power has the characteristics of strong adaptability to materials, continuous production, a large crushing ratio, and easy to adjust the fineness of .

Our indexable ball end mills come in two types: steel and carbide. The premium indexable alloy steel end mills have excellent strength, precise H6 tolerance shanks, and are nickel plated to prevent corrosion and improve lubricity.. The indexable carbide ball end mills have the same rigidity as solid carbide end mills, so they are very stable in the cut, and capable of excellent .

Vertical ball mill is a mill in which the barrel is vertically fixed and the grinding medium is driven by the grinding shaft ... There is an opening on the cylinder body to facilitate the maintenance of the mixing shaft and the replacement of mixing medium. ... The stirring shaft of the vertical ball mill drives the steel balls to turn in a ...

From the start of the compressor, Vibration in axial direction in all 3 motors are on higher side. Axial 6 to 9 mm/s, values are not very steady in all 3 motors. Motor is having series of 1X harmonics from 120X in horizontal and vertical direction, maximum amplitude at discrete peaks are lesser than mm/s.

Turning Grinding Of A Rotary Kiln's Support Roller. Rugby Cement Ball Mill Drive Shaft Recovery In a typical ball mill orbital turning operation the inner bearing ring of the orbital machine is attached to a temporary bearing housing on the ball mill casing with the outer bearing supported on a temporary shaft extension.

Vertical Roller Mills (VRM). Roller press with Ball mill. Ball Mill. Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years. Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills.

Cement ball mill repair. The Rugby Works ball mill had been operational for over 35 years and was due for replacement, indeed the new machine was on order, but the journal failed before the new mill was due for delivery. The mill is the last on the production line and blends and grinds clinker and gypsum together with other additives to make ...

Even in a Mixer Mill, which generally uses less grinding media and therefore creates less friction than a planetary mill, temperatures exceeding 100 ºC are not unusual. When using spherical media in a ball mill, the only way to reduce friction is to reduce the number of pieces of media however, this in turn reduces the efficiency of grinding.