Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel. 98 of the mined iron ore is used to make 12, 2021 Sintering is an intermediate process in steelmaking that turns iron ore, coke and other raw materials into an ironrich product and feedstock for blast furnaces.

material and lot iron ore process

Iron is extracted from iron ore in a huge container called a blast furnace. Iron ores such as haematite contain iron (III) oxide, Fe2O3. The oxygen .

· Iron ore is another raw material that serves little purpose when it is embedded in rock formations. This rock put through a smelting process, meaning it is heated to high temperatures until its oxygen content is reduced. In this way, the raw ore is converted to the iron used in construction and manufacturing.

· The process of manufacturing pig iron is a bit complied. The following steps explain the same as simply as possible. Raw MaterialsThe raw materials used in the blast furnace to produce highquality pig iron are ironore, coke, limestone, and sinter. Now, these iron ores are nothing but oxides of iron that contains other materials like ...

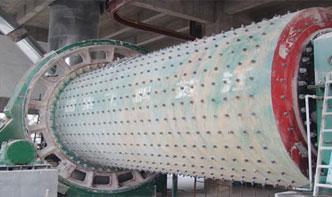

· People who know the mining machinery industry know that my country has rich mineral resources, and iron ore is a relatively common metal mineral and is a very important raw material in the steel industry. Crushing and processing can realize its appliion in different industries. In the process of iron ore processing, the crusher can be said to be .

Because iron was a far superior material for the manufacture Posts Related to material and lot iron ore process . Read More. Iron Ore Processing for the Blast Furnace. Iron Ore Processing for the Blast Furnace steel from lowgrade iron ore requires a long process of of separating the iron from the noniron material.

· An Infographic of the Iron and Steel Manufacturing Process. Steel production is a 24houraday, 365dayayear process, dependent on a consistent supply of raw materials and huge amounts of energy. According to the World Steel Association, world crude steel production has increased from 851 million tonnes (Mt) in 2001 to 1,606 Mt in 2013 and ...

· Processes. Today's metallurgical processes utilise advanced information technology for process control and monitoring of operations. A precondition for the efficient production of high quality steel is, nevertheless, a proper control of the raw materials. The two most important raw materials for the production of steel are iron ore and scrap ...

Coal, Iron ore, Mineral ore, Grain, Cement Woodchips loading in bulk Solid bulk cargo Any material, other than liquid or gas, consisting of a combination of particles, granules or any larger pieces of material, generally uniform in composition, and loaded directly into the cargo spaces without any intermediate form of containment.

material in the disc granulator and in Eirich intensive mixer. The research was conducted with high concentrate share in the sintering mixture from 0 to 100 %, where 100 % means the share of the ironbearing materials in the sintering mixture Table 1. Table 1 Share of the ores and concentrates in the mixture No Iron ore Iron ore concentrates Disc

Approval. . Final text received or FDIS registered for formal approval. . Proof sent to secretariat or FDIS ballot initiated: 8 weeks. . Close of voting. Proof returned by secretariat. 60.

iron and vanadium are extracted by the blast furnace – converter procedure. Titaniumcontaining ores of the deposits like Medvedevskoye and Kopanskoye ones are generally considered as a .

· Iron ore prices have been supported by hopes that China, which accounts for more than 70 percent of global seaborne iron ore trade, will invest heavily in infrastructure and construction to revive an economy devastated by the coronavirus. The increase of iron ore has brought a lot of investing opportunities to iron ore producers.

process flow in a iron ore crushing unit Know More. The production of pig iron from crushing plant waste Crushing plant is one of important processing units in mining industry Process sequences in mineral mine processing are started with crushing plant unit, to reduce bigger mineral size into desired size to use in the next processing In the iron ore mining industry, .

· When the iron ore is extracted from the mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher's CSS before the crushing stage. A static screen is used to divert the fine particles for crushing.

(3) Sponge Iron Process: As the name implies, the spongy iron is obtained by the reduction of lumpy iron ore or iron ore pellets from the oxide form into the metallic state. The iron content of the product so obtained varies from 90% to 94% and the balance represents the traces of gangue and residual iron oxide.

EXTRACTION OF IRON IN A BLAST FURNACE Iron is also below carbon in the reactivity series, so therefore carbon can be used to reduce it (note: reduction can also mean to remove the oxygen from a compound). This is done in a blast furnace. The most common ore of iron is called haematite (iron(iii) oxide). Its formula is Fe 2 O 3.

Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine. The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is red; magnetite .

Iron Ore Materials Handling Introduction. Materials Handling addresses the problems that arise when high moisture, sticky ores are transported through bins and chutes and onto ships across the supply chain. In such a system, the overall performance is only as good as the weakest link. For example, a blockage in a single transfer chute can ...

· A mathematical model of drying and preheating processes in a traveling grate was presented based on the laws of mass, momentum, heat transfer, and drying semiempirical relations. A field test was systematically carried out in a traveling grate. The effects of pellet diameter, moisture, grate velocity, and inlet gas temperature on the pellet bed temperature .

For this process, coking coal is turned into coke, an almost pure form of carbon, which is used as the main fuel and reductant in a blast furnace. Typically, it takes tonnes of iron ore and around 450kg of coke to produce a tonne of pig iron, the raw iron that comes out of .

The materials science tetrahedron defines the scope of materials science and engineering. The tetrahedron emphasizes the four interdependent, distinct aspects of materials science: processing, structure, properties, and performance. These "corners" of the tetrahedron may seem simple, but from an eduional point of view, it is critical to identify what students learn .

Dec 18, 2016· The process is most popular with many miners because it is low cost, especially when processing lowgrade ores. To use the cyanide process the silver being in the ore should have smaller particles, should be able to react with the cyanide solution, the silver should be free from sulfide minerals and other foreign substances.

Metal and Iron Ore Mining. The Iron Age began around 1200 BC, ending the Bronze Age that preceded it and paving the way to man's mastery of metal. Individuals during this period began extracting iron ore to forge tools and weapons. The reason revolves around Iron being one of the most abundant metals found on earth.