The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite. The ore rocks are quarried and crushed to smaller pieces of about 6 inches. Secondary crushers or hammer mills then reduce them to even smaller size of 3 inches.

crushing of clay for alum production

This is how I make crucibles for metal casting. 50/50 w/w grog (crushed fire brick) to fire clay with the barest minimum of water to make the mixture adhere ...

Jan 31, 2020 · Aluminum cans are consumed in huge quantities mainly in two types of containers: 0,33 and 0,50 l. Large production volumes justify the highspeed, highprecision production lines. Moreover, these various basic aluminum cans have the same diameter, they use the same cover and differ only in height.

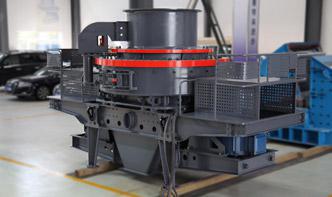

Stone Crushing Production Line Rock Crushing Plant Stone . the working process of stone production line: big size stones are transferred to primary crusher through vibrating feeder from hopper for first crushing, then the crushed materials are transferred to impact crusher through belt conveyor for secondary crushing. the crushed materials will be transferred to the .

Waste aluminum crushing separation line, dedied to the treatment of waste The Broken Bridge aluminum, aluminum alloy profiles, etc. The production line has advanced efficiency. It can fully separate aluminum iron, plastic and plastic strip.

CP Manufacturing introduced the world to automated aluminum can recycling in 1976. Today, with more than 10,000 pieces of our ultraefficient, lowmaintenance separating and processing equipment in operation, we continue to lead the industry in anticipating and meeting its needs. CP recycling equipment is built to last. Whatever your processing volume, whatever your need, .

A process for recovery of aluminum from clay comprising treating the crushed clay with water in the form of a fine mist, and in an amount sufficient to form compact surfaces on the particles .

Nov 11, 2013 · In the process of production and processing of limestone, mainly will be used the following equipment: mill (raymond or highpressure grinding), jaw crusher, hammer crusher, impact crusher, sand making machine and other equipment. Crusher equipment will be the first to use large chunks of limestone crushing.

Eia Reprt For Stone Crushing Factory In Ruwanda. News Introduction:Eia for a crusher plant environmental impact assessment the subject of this eia is the obajana cement plant and the associated manufacturing of cement entails crushing grinding Assessment For Stone Crusher. Environment impact assessment report miga by the dust emitted during the site .

Geoscience Australia is the national public sector geoscience organisation. Its mission is to be the trusted source of information on Australia's geology and geography to inform government, industry and community decisionmaking. The work of Geoscience Australia covers the Australian landmass, marine jurisdiction and territories in Antarctica.

Feb 29, 2016 · Crushing and Comminution The selection of an appropriate crushing and comminution circuit for a specific ore type is one of the most important key aspects in a new gold project. The importance is related to the fact that the capital and operating costs for generated for these operations represent the major part of the plant operative costs (65 ...

Standard molecular sieve 5A is made from zeolite powder 5A (>70%) and binder. Binder is clay, which has little adsorption capacity. Binderless 5A transforms clay binder to zeolite 5A. That means zeolite 5A composition in binderless molecular sieve 5A .

Crush strength is measured in the amount of pressure (lb. or kg.) it takes to crush a single granule. Crush strength for fertilizer and soil amendment products generally falls around 46 poundforce (LBF). Factors that Influence Crush Strength. The crush strength of a product can be influenced by several factors – most notably, the binding agent.

Crushing Plant Flowsheet DesignLayout Flow Sheet Of A Two Stage Crushing Plant Open Circuit Crushing Plant Flowsheet DesignLayout Crusher Plant LayoutCrushingScreeningMost crushing plants are now designed on the lines shown in Fig 1, which is a diagrammatic view of a twostage arrangementThe ore from the mine is dumped in the coarse ore bin, from which an .

Before mining can commence the land needs to be cleared of timber and vegetation. Alongside this process may be the collection of seeds and/or saplings, for inclusion in a seedbank, which will form the basis of postmining revegetation of the site. Next the top soil is removed and is usually also stored for replacement during rehabilitation.

Cold crushing strength test authorstreameb 13 2014 it tells us how much load that refractory can bear in cold conditionscold crushing strength this test helps in determining the strength of a brickt tells us how much crushing. The clay brick has a cold crushing strength of kg/cm 2, porosity of % and bulk density of g/cm 3.

Clay manufacturing can be either via a dry or wet/slurry process. Manufacture is comprised of a number of phases; extraction, blending (where necessary), crushing and drying. Each stage .

Sep 22, 2015 · Manzhurin, Sidorina, Medvedeva,Dostayeva Karaganda State Technical University, Kazakhstan CALCULATION OF KEY PARAMETERS ROLLER OF THE CRUSHER Roller mills are used for small and medium crushing of coal, ore, limestone and other materials. Roller crusher (Figure 1) consists of two rolls 3 and 5 of the same diameter, .

The type of clay body that is formed depends on the kind of rock that is initially eroded. It also depends on the sediment that it picks up on its journey. Once a commercially produced clay body has been mined from the ground, it is processed in a plant. This usually involves, amongst other things, crushing, grinding, and screening (3).

May 10, 2020 · Depending upon the type of manufacturing process, the crushing and grinding process varies and the raw materials are dried up before crushing for dry process. Mixing or Blending: In this step with clay in the desired proportion, the grinded raw material like limestone is blended or mixed, and to get a homogeneous mix, it is mixed well by the ...

About product and suppliers 1589 aluminum crushing machine products are offered for sale by suppliers on of which crusher accounts for 10 plastic crushing machines accounts for 7 and other metal amp; metallurgy machinery accounts for 2. A wide variety of aluminum crushing machine options are available to you such as canada japan.

Feb 17, 2019 · Clay is sticky. sizing crusher is best choice for crushing the sticky material. 1. The crushing work conditions: Raw material: clay with 10% of stones The feeding size: 200 The discharged size: less than 100mm Capacity: 300400t/h Solutions Model: FP 63AS Power: 200KW Weight: 22 ton Dimension: refer to the attached CAD drawing the [.]

Jaw crushers. 4. Roller crushers. Hammer Crushers: Raw materials from quarry are now routed in Cement Plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding. Generally, limestone is 80% and remaining 20% is the clay. Impact Crushers: Impact crusher is best ...