Industrie Bitossi has always played a major role in the grinding of ceramic body, glaze and minerals, thus excelling in the innovation and tecnology adopted for the development of grinding charges which radically changed the working conditions of ball mills and optimized their performance. PRODUCTS.

role of grinding media of ball mill

Molycop manufactures grinding balls to exacting internal specifiions at its grinding media production facility across the globe. Balls for use in mineral processing ball milling operations are designed for maximum abrasion resistance using high carbon content and high hardness levels.

Grinding media for ball mills. Grinding media are necessary in many industries currently. Their main function is grinding, of course. They are used in different coal, lime and construction material production processes, in metallurgy for processing gold, uranium, copper, zinc, nickel, titanium ores, etc.

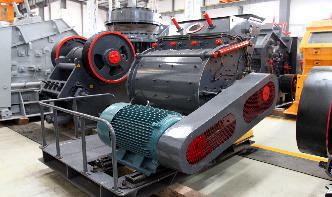

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a ...

Mar 13, 2014 · 3) Make the appropriate proportion of materials, balls and water. Loading capacity of the grinding media has a major impact on the efficiency improvement of ball mill. If the loading capacity is too small, materials impacts and grinding will be small, while excessive load reduces feeding, grinding interaction will be increased.

Dec 23, 2013 · Rod mill is similar to ball mills but it uses long rods for grinding media. Autogenous mill is a selfgrinding mill which is used in breakage of larger rocks. SAG (SemiAutogenous Grinding) mill is an autogenous mill which uses grinding balls, it is similar to ball mill but has large diameter and short length.

Dec 26, 2017 · MagenetMonetization 01 > Several factors affect the efficiency of a ball mill for cement grinding. In this article, we shall be looking at some of these factors that have been proven to influence grinding efficiency: Mill Geometry And Speed According to Bond (1954), the grinding efficiency of a mill depends on the ball mill diameter, size of the [.]

Grinding media can be divide into cast grinding media and forged grinding media, which are widely used in mining, cement plant, power station, etc. While for cement plant, cast grinding balls are the best choice. Forged steel balls are widely used many areas, such as largescale mines, gold mine, copper ores, alumina ores, iron ores, metal ores ...

Increased Power Consumption Power consumption by ball mills is directly proportional to mill load/charge volume, and specifically the amount of grinding media added at a particular time. Increased power consumption normally results in high electricity bills.

The Disadvantages of Ball Mill: 1. Low working efficiency and high unit electricity consumption. 2. Heavy equipment. Largesized ball mill weighs several hundred of tons so that the onetime investment is high. 3. Low rotary speed. 4. High consumption of grinding media and lining board. 5. Loud noise and strong vibration during its working process.

Aug 03, 2021 · During the use of the ball mill, the choice of grinding media is very important. Grinding media is affected by many factors such as material, filling amount, shape, particle size, etc. In the grinding process, using different grinding media for different materials, models, and equipment can reduce production costs and improve production efficiency.

The grinding media is actually alumina particles held in place by an SiO2 glass phase. Sizes from 400 microns to over 1 inch in beads, balls, satellites (ball with bands) and cylinders. Low to medium cost, small sizes are more costly. Fused Zirconium oxide Grinding Media ( ) Smooth surface leads to low mill wear and longevity. Sizes ...

Grinding rise, circular motion is the cycle of falling. In addition, during the rotation of planetary ball mill grinding body also produces sliding and rolling, thus grinding, abrasive action between the liner and the material, the material ground. Due to the feed end of the continuous feeding of new material, so that between the discharge end ...

Jul 05, 2017 · Philex Mill uses steel balls as grinding media. Currently we use 80mm and 90mm diameter steel balls. All ball mills are filled with grinding balls at 3235% load. Grinding ball consumption is at 340 to 370 grams per ton of ore milled. Grinding media (steel balls) is the working part of a Mill. It will.

Therefore, the selection of a reasonable cement grinding system plays a key role in energysaving and consumption reduction of cement plants. Nowadays, the cement grinding system has developed from the previous single ball mill system to the ball mill + roller press system and vertical roller mill system.

Ball top size (bond formula): calculation of the top size grinding media (balls or cylpebs):Modifiion of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modifiion of the ball charge in order to improve the mill efficiency:

Grinding aids are generally added to the ball mill to reduce electrostatic agglomeration of fine particles and to reduce coating formation on grinding media which reduces grinding efficiency. The optimum addition rate should be determined carefully to enhance grinding efficiency.