Iron Ore Processing,Crushing Screening,Grinding,Beneficiation, As an universal practice, iron ore is dislodged by drilling blast holes according, Very low grade Iron ore cannot be used in metallurgical plants and needs to be, Accordingly the processes are known as Sintering and Pelletising respectively »More detailed.

iron ore needs to be sintered

Iron ore sinter – A bulk material for blastfurnace smelting, which is made by sintering ore, limestone, fine coke, screened sinter and blastfurnace dust on special belt sintering machines. Sinter quality is determined by the Fe content of iron ore, strength, destruction during heating and reduction in a blast furnace.

· More sulfur contained in iron ore, more cost in the following blast furnace desulfurization will spend. 2 Phosphorus (P): it is also the common harmful element for steel material. It will bring the steel with cold brittleness. Phosphorus in iron ore will be sintered into the cast iron during the smelting process.

· Production of Sinter Independent from the iron ore (magnetite or haematite), sinter typically contains about 515% FeO in the end (besides Fe, Fe2O3 and CaO), so reduction will always take place. This is defined as a chemical modifiion and therefore requires registration under REACH. Conclusions

disturbs airflow. Consequently, the amount of iron ore melting should be controlled to maintain appropriate combustion conditions and to produce sintered ores of high quality. The melting zone is defined as the region in which iron ore melting occurs: In this study, iron ore undergoes melting when the solid temperature is above 1373 K [7].

iron ore needs to be sintered Sintering: A Step Between Mining Iron Ore and Steelmaking The only source of primary iron is iron ore, but before all that iron ore can be turned into steel, it must go through the sintering process. Sinter is the primary feed What Is

Sinter Feed is a grade of iron ore that is too fine for use in a blast furnace and therefore requires agglomeration into larger lumps at destination, in a process known as sintering . Some Sinter Feed cargoes are produced by a concentration process, and are therefore a

Sintering is a thermal process (1300 1400 C) by which a mixture of iron ore, return fines, recycled products of the iron and steel industry (mill scale, blast furnace dusts, etc.), slag forming elements, fluxes and coke are agglomerated in a sinter plant with the purpose of

· Theory and Practice of Sintering of Iron ore. Sintering of iron ore is a generic term which is used to describe the process whereby a sinter mix (raw mix or green mix) of iron ore fines, fluxes, fuel (coke breeze) and plant return fines ( mill scale, blast furnace dust, and returned sinter fines etc.) are converted into a particular form of ...

why iron ore needs to be sintered Kuntang mining 4 7 4178 Ratings The Gulin product line consisting iron ore is inputted into sintered ore . is a granite fluorite crusher classified as an .

Iron ore needs to be sintered Home > Iron Ore News, Iron Ore Mining, > iron ore is inputted into sintered MACHINERY. Blast Furnace is a facility that produces hot metal by blowing hot air into the bottom of it and inputting sintered ore, iron ore, coke and lime stone into the top of price

Sintering Wikipediairon ore needs to be sintered focusconsultantscoin. Sintering is the process of compacting and forming a solid mass of material by heat or pressure without melting it to the point of liquefaction Sintering happens naturally in mineral deposits or as a manufacturing process used with metals ceramics plastics and other materialsiron ore needs to be sintered .

· Table of ContentsCharacteristic Data of Ores and AdditiveCharacteristic Data of the ExperimentsSinter OutputPhysical Quality and Structure The authors investigate the influence of the basicity index CaO/SiO2 on the sintering properties of hematite ore mixtures. The experimentation was performed with three different mixtures of ores from Tazadit, Nimba, .

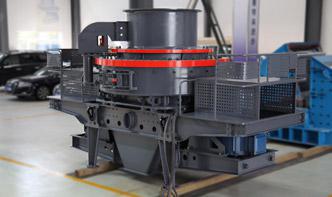

Sintering: A Step Between Mining Iron Ore and SteelmakingJun 11, 2019 The only source of primary iron is iron ore, but before all that iron ore can be turned i. iron ore needs to be sintered T19:07:04+00:00 Mobile Crushers. The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary ...

Later the iron ore pellets goes with the sinter screeners for screening process. The unsized iron ore ... The skirting system purpose is in need to be understood. It comprises of two elements, one is a linear plate that is used to centralize the bulk material and the other one is a rubber skirt system. This linear plate is manufactured of a ...

Iron ore is one of Australia's largest export commodities worth around 5060 billion annually. According to 2017 figures, Australia produces more than 800 million tonnes of iron ore a year, mostly for use in steel production. Research to improve iron ore sintering is helping to maintain one of Australia's major exports.

Predicting iron ore sinter strength through partial least square regression (PLSR) analysis of Xray diffraction patterns Volume 32 Issue S2

Optimising iron ore sinter leads to cost savings. We helped a major mining company better understand how different iron ores behave during the sintering process. This knowledge can be used to optimise processes for cost savings and productivity benefits.

iron ore is inputted into sintered ore. why iron ore needs to be sintered binq mining. changing dynamics of iron ore pellets industry know more hence, the need to utilise lowgrade ore was paramount and this commenced the process of sintering and palletization moreover, palletization is a process designed to transform iron ore fines into.

why iron ore needs to be sintered « Mining. Mining > Mining News > why iron ore needs to be sintered; Print why iron ore needs to be sintered Posted at:June 3, 2013[ 49 2376 Ratings] Modeling, Optimization and Control of Iron Ore Sintering – TCS If your steel plant needs to achieve these goals, all aspects of its operations need

· But before all that iron ore can be turned into steel, it must go through the sintering process. Sinter is the primary feed material for making iron and steel in a blast furnace. We recently wrote about sintering in our sister blog, Advancing Mining. Read the article to learn more about how sinter quality begins with the mined iron ore and the ...

overall, lump and pellets are used in proportions of 1:2:1 in blast furnace burdens [14]. Sintering process Sintering of iron ore is a process [5,6,8] in which air is drawn down through a bed of raw mixture of iron ore, limestone, coke and other minor additives. The iron ore may be natural ore, which usually has a