Synthesis of nano materials by topdown method: Advantages and disadvantages. One of the main advantages of mechanical methods is the relatively low cost, high productivity and the ability to produce materials with less than 20 nm accuracy. However, depending on the type of method, the final particles of the product do not have an orderly shape ...

difference between milling and crushing in ceramics

Aug 11, 2021 · It's not uncommon for people to confuse a crush for true love, as they can bear a lot of resemblance at first.. But it's crucial to note that there's, in fact, a major difference between crush and love.. Temporary infatuation (aka a crush) presupposes a strong attraction and a physical connection, while love carries a deep affection and longlasting romantic feelings.

Ball Mill Is The Key Milling Equipment After Material Has Been Crushed. 1. The ball mill can grind various materials and produce ore pulp. 2. It can be divided into wet and dry grinding method. Usually we adopt the latter. 3. It is full of high .

Wet Grid Ball Mill |. Capacity: Feed Size: ≤25 mm. Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc. The size of ore shall not exceed 65mm and the best feed size is under 6mm. The effect in this job is better ...

Jul 09, 2014 · Figure 3 Coining, bottom bending, and air forming affect stressstrain properties differently. The curved line in the air forming zone shows how springback changes at different bend angles. In bottoming and coining, bending methods that usually produce 90degree bend angles, the line curves to the right of the vertical axis, showing how the metal springs forward .

Jul 05, 2020 · The endrunner mill consists of a weighted pestle mounted eccentrically in a ceramic, granite or metal mortar, which is rotated by a motor. The pestle rotates by friction and is free to rise and fall in the mortar so that its grinding action involves both impact and shear, the material being crushed and rubbed between it and the rotating mortar.

DOVE Ball Mills are deigned for either wet or dry grinding of materials, in various models, and in accordance to the processing and the crushing plant design, to er to the liberation size of the minerals and the hardness of the ore. DOVE supplies two different kinds of ball mills Grate type, and Overfall type.

Jan 26, 2020 · Differences between drill and end mill. Drill (Drilling) End Mill (End Milling) Drill is the cutting tool used for drilling operation. Drilling is one machining process used to originate a hole on a solid surface. End mill is the cutting tool used for end milling operation. End milling is a machining process used to cut features like slots ...

Milling Grain vs. Purchasing Crushed. I recently purchased a Barley Crusher and had my first go at hand cranking 16 pounds of grain today. Aside from the labor of hand cranking, I'm seriously considering just returning the mill and purchasing already crushed grain. I am only brewing about 10 times a year and considering the labor, cleanup, etc.

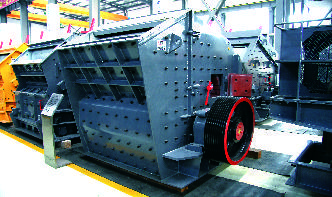

Key Differences Between a Lump Breaker and a Hammermill. As we've already mentioned, a hammermill will break down more solid materials then a lump breaker. Lump breakers use a lower impact force and larger operating clearances between the blades and the breaker bars. This means they are ideal when a gentle granulation, coarse size reduction ...

Cryogenic milling, or cryomilling, is the process of using liquid nitrogen to lower the temperate of the material and/or the milling process. AVEKA 's cryogenic hammer mills can typically reduce the particle size from small pellets down to the 100s of microns. Cryomilling can be used for:

Mar 13, 2020 · In the end, both types of belts are excellent belts. The decision will depend on a mixture of use and your preferences. If you need a grit higher than 120, ceramic is likely the better choice. Ceramic belts do last longer, but they are also slightly more expensive than zirconia belts. Heat buildup is a common issue with metalwork.

difference between milling and crushing . Abstract The use of ceramic beads as grinding media mills and stone crushers rod mill What s the difference between Ball Mill and Raymo . BDSM Library Hirst Hall .

Dec 02, 2014 · The process of human civilization is the process of refining,in this way grinding equipment is the promotion of crushing equipment,but now we can found many mobile crushing equipment,if youwant ...

Sep 17, 2019 · Milling says : Avoid interrupted cuts. An interrupted cut is one where the tool alternately enters and leaves the workpiece during the cut. Because cast iron has relatively low tensile strength, the tendency of the cutting forces it to break out the edge of the casting as the tool leaves the work.

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter ( Figure ). The feed can be dry, with less than 3% moisture to minimize ball .

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.