The production of iron ore fines occurs at the early stages of processes in the integrated steel plant. This causes iron resource loses and also causes higher cost of utilization. Generation of iron waste from steel Trading and Services, are the top significant suppliers of Iron Ore in the domestic and international markets. We have years of experience in supplying the .

usage of waste product of iron ore

· Iron Ore Smelting Process Using Modern Blast Furnaces. Although the basic ingredients of an iron ore blast furnace has changed little over the last hundred years or so, the furnaces themselves have been modernized to improve efficiency and the purity of the iron and steel. The furnace has a more efficient shape to suit automation, with the contents of iron ore, .

In the production of iron, iron ore, iron scrap, and fluxes (limestone and/or dolomite) are charged into a blast furnace along with coke for fuel. The coke is combusted to produce carbon monoxide, which reduces the iron ore to a molten iron product. This molten iron product can be cast into iron products, but is most often used as a feedstock for steel production. Blast .

chemical reaction involved with cement production generates CO₂ as a byproduct. Achieving a low carbon industry is of paramount importance, not only to reach the 2050 carbon neutrality target, but also to allow economic growth for EU companies and workers. The more challenging issues lie in core highly emissive chemical processes such as the production of cement or .

Iron ore Wikipedia, the free encyclopedia Iron is the world's most commonly used metal steel, of which iron ore is the key ingredient, representing almost 95% of .Iron ore Wikipedia,,Posts Related to what are the byproducts of mining iron,project report on granite waste to .is a waste product from iron ore Gulin machine in iron ore processing plant, is

iron ore waste utilistation use of iron ore waste products Coal Surface Mining use of iron ore waste products Description Iron ore Wikipedia the 12/04/2014 . uses of waste products of iron ore « mill gold . usage of waste product of iron ore – 19 Jul 2013 . Get the price of machines: More details:b>. uses of waste ...

· In the longterm mining and production process, a large number of waste rocks and tailings are produced, ... And some iron ore tailings which contain much silicon and iron can also be used as iron and silicon corrective materials. 7. Raw materials to produce all kinds of bricks and tiles At present, coal gangue bricks have become one of the main building materials .

· To valorize these waste alysts, a new technology for the recycling of waste alysts in steelworks was proposed, in which waste alysts were added to the iron ore sintering process for preparing titaniumbearing sinter for blast furnace hearth protection. The effects of adding the waste alyst on sinter product quality indexes were investigated by .

Iron Ore Pellets are formed from beneficiated or run of mine iron fines. The iron is usually ground to a very fine level and mixed with limestone or dolomite as a fluxing agent and bentonite or organic binders as a binding agent. If the ore is a Hematite ore, coke or anthracite coal can be added to the mix to work as an internal fuel to help fire the pellets. This mixture is blended .

This paper studies the technological feasibility of using iron ore tailings as additives in cement pavers for the optimization of the mechanical properties and color, to study the physical, chemical, optical and morphological properties of the tailings, they were characterized for the composition, mineralogy and granulometry. To optimize the procedure of preparing .

Usage Of Waste Product Of Iron Ore Jaw crusher ball mill. Usage Of Waste Product Of Iron Ore. However the specific gravity or unit weight of waste rock from the mining of iron ore and taconite will be considerably higher than that of conventional aggregates the specific gravity of waste rock can be expected to range from 24 to 30 for most rock typ,Usage of waste .

Wrought iron contains less than % carbon and was made by reducing iron ore in the solid state, and then hammering to remove the slag. Because it could be bent and hammered into shape, it was used for 'traditional' gates, garden furniture and other decorative products. These are now made mostly from steel, and genuine wrought iron is no longer produced in any .

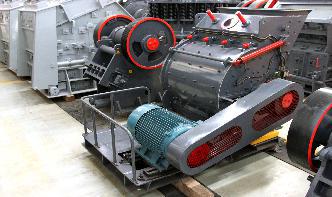

usage of waste product of iron ore Grinding Mill China. Iron Ore Processing | Home. The midsized company JOEST + Co. KG from Duelmen in Germany is installing a hightech system for processing iron ore pellets in Narvik,, the northernmost city of Sweden, is home to an iron ore mine of . Get More; uses of waste products of iron ore .

usage of waste product of iron ore pneus use of iron ore waste products xcellencecoin Is a waste product from iron ore If regulated well the collection and separation of waste, The large iron ore, What Are the Main Uses of Iron Ore? Apr 11, 2020· Iron ore is the main ingredient in steel, which makes up 95 percent of the metals used in the world per year. Two billion metric .

Replacing fossil fuelbased feedstocks and reactants (, ammonia production, chemical industry, iron ore reduction in the steel industry). • High energydense fuels for propulsion over long distances (, shipping, aviation, roadfreight). • Providing resilience to the electricity system as a fuel for peaking power plants and interseasonal balancing (, where the .

· Iron ore can be mined from all places in the world but to be commercially viable, the percentage of iron in this iron ore needs to be at least 20%. This is because lower iron content in the ore will render all the money and effort exerted in mining the ore from under the surface of the earth a big waste. This is why minerals near the surface of the earth and containing as a .

· Extraction of Iron from its ores. Extraction of iron or its metallurgy is the process of obtaining this metal in a form where it can be put to practical use, and this process of extraction consists of three stages: Ore dressing, Reduction of ores and Iron production. Extraction of .

Due to the recycling of the waste gases through the sinter plant in order to reduce dust emissions, ... Six major countries in iron ore mine production from 2010 to 2013 are China, Australia, Brazil, India, Russia, and Ukraine. In the United States, in 2013, Michigan and Minnesota produced 99% of the usable iron ore in 11 iron ore mines with 9 concentration plants and 9 pelletizing .

Usage Of Waste Product Of Iron Ore Grinding Mill China. The iron occur in Fe mineral ores contains impurities of Phosphorus, sulphur and high alkali as well as impregnations of waste rock. To produce a metallurgy treatable concentrate the ore has to be grind for mineral liberation, enriched for concentration and dewatered for transportation. Get Price. Development Of Value .