· Pelletizing feed preparation and mixing: the raw material (iron ore concentrate, additives—anthracite, dolomite—and binders are prepared in terms of particle size and chemical specifiions, dosed, and mixed together to feed the pelletizing process; Balling process: the green pellet is the rolled pellet without any thermal process.

what is feeder in iron ore screening plant

· To process iron ore from Kumaraswamy Iron Ore Mine, the setting up of SP2 Screening Plant of MTPA capacity is under progress with a future provision of increasing its capacity to MTPA.

6) Pellet screening /HL Segregation Process of receiving raw material The loion of a pelletizing plant affects the method of receiving raw materials such as iron ore, additives and binders. Pretreatment process of Iron Ore Fines In the pretreatment process, iron ore fines are ground into finer size, suitable

what is feeder in iron ore screening plant Coal Surface Mining . what is feeder in iron ore screening plant Description : vibrating screen feeder for copper ore screening plant – 29 Oct 2013 . Screening Machine.

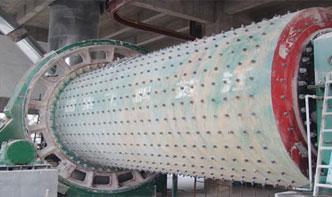

Iron ore must be shipped in bulk for maximum economy. Pretreatment process In this process, the iron ore is ground into fines having qualities required for the subsequent balling process. The pretreatment includes concentrating, dewatering, grinding, drying and prewetting. In general, lowgrade iron ore is ground into fines

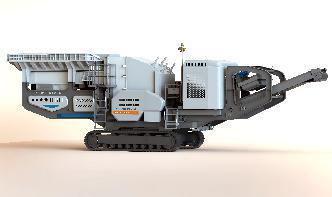

Iron Ore Crushing Screening Plant. Iron ore crushing and screening process photo ore mining process and iron ore mining equipments mining and processing of iron ore involves coarse crushing and screening iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening this is usually so efficient that lower grade ore .

Outotec's screens offering consists of banana screens, horizontal screens, inclined screens, mobile screens, portable screens, and ultrafine screens. Each screen type has its benefits and restrictions. Our screening experts are happy to work with you to find the optimal screening equipment for your appliion. High performance.

The average iron content of pellets is 63 percent. Process Description25,41 Processing of taconite consists of crushing and grinding the ore to liberate ironbearing particles, concentrating the ore by separating the particles from the waste material (gangue), and pelletizing the iron ore concentrate.

· Vibrating Feeders: Vibrating Feeder is a kind of lineardirection feeding equipment, in the mineral ore rocks processing plants. It sends .

How does iron ore screening feeder work,Our company is a largescale heavy enterprise that taking heavy mining machinery manufactory as main products and integrated with scientific research, production, and marketing. We are concentrating on producing and selling machines such as jaw crusher, cone crusher, hammer crusher, ball mill, sand maker, mobile crushing plant

How A Iron Ore Crushing And Screening Plant Works XSM. Supply How A Iron Ore Crushing And Screening Plant Works How A Iron Ore Crushing And Screening Plant Works Our products(How A Iron Ore Crushing And Screening Plant Works) have been sold to many countries and areas of Southeast Asia, East Europe, South America, the Middle .

Largest Scandinavian Iron Ore supplier counts on JOEST screening technology. The million Euro project comprises of a new, turnkey screening house to process iron ore pellets for worldwide shipping. PROCESSING PLANT FOR THE SCREENING OF IRON ORE PELLETS. STORAGE BUNKER SYSTEM. BUNKER DISCHARGE FEEDER.

Iron Ore Processing Crusher Feeder Screen Company. Iron Ore Is The Key Raw Material For Steel Production Enterprises Generally Iron Ore With A Grade Of Less Than 50 Needs To Be Processed Before Smelting And Utilization After Crushing Grinding Magnetic Separation Flotation And Gravity Separation Etc Iron Is Gradually Selected From The Natural Iron Ore

Iron and Steel Manufacturing Industry Description and Practices Steel is manufactured by the chemical reduction of iron ore, using an integrated steel manufacturing process or a direct reduction process. In the conventional integrated steel manufacturing process, the iron from the blast furnace is converted to steel in a basic oxygen furnace ...

inplanT experTise for iron ore For the iron ore exploration and mining industries, ... crush and screen. Sometimes this is extended to include scrubbing, grinding and ... improvement of feed particle size, and better control of pulp densities.

As good quality iron ore deposits are depleting very fast, beneficiation technologies have to be adopted to meet iron ore demand. Agglomeration technologies such as pelletization/sintering have to be added to steel plant so that concentrates can be used as feed material.

Normally to reduce the big ore lumps to small particles, two to three stages crushing is required. Prominer has the ability to supply complete crushing and screening system, including various crusher, screen, belt conveyor, iron remover, etc. For minerals with different properties and hardness, we can recommend suitable crusher accordingly ...

Iron ore fines (010 mm) which were a result of mechanized mining could not be charged in a Blast furnace because they reduce the permeability of burden in a blast furnace. These iron fines that were generated at mines could not ignored because of their i) .