Apr 05, 2012 · American Smelting and Refining Company ... The companies primary business has always been copper mining and refining but has also interest in lead processing. Upon the many products manufactured by American Smelting and Refining Company, various grades of Babbitt were included. ... A tin based babbitt plus Nickel. While the exact composition is ...

tin processing and refining

Sugar Cane: Refining Process. Today, we're looking at the process for sugar cane, and how it gets from the field to your kitchen pantry: 1. Sugar cane stalks are harvested from fields in loions such as Florida, Louisiana and Texas and then sent to a nearby sugar mill. 2. At the sugar mill, the sugar cane stalks are washed and cut into shreds.

The Harris process of lead refining. Harris process is a wellknown technology for purifiion of lead from alloying elements (impurities) antimony, tin and arsenic, this process use sodium nitrate as an oxidizing agent. Sodium nitrate..

Mar 07, 2022 · Contained tin production up 10% from the prior ... tin grades of processed material and processing ... smelting costs and deductions, refining and freight, distribution, royalties and product ...

Tin Technology and Refining and the Nathan Trotter Company ... marketing and technical appliions engineers to establish a higher level of sales thru total processing solutions.

How It Works. From pickup to payment, we make the process of recycling your tin scrap as simple and efficient as possible. We also pride ourselves on tailoring a recycling program that fits every company's unique needs.

The objective of the refining process is to remove almost all copper (Cu), antimony (Sb), arsenic (As) and tin (Sn), since soft Lead are not allowed to have more than 10g per ton of these metals. Pyrometallurgical Refining Pyrometallurgical Refining is performed in liquid phase, which means that the crude Lead must be melted to temperatures ...

Payments will then be made via cheque, bank transfer or toll refining service. Toll refining is the service of reclaiming precious metals from a material set against a processing cost. This form of precious metal refinement involves weighing, homogenising, sampling and assaying the object to clarify its contents.

Tin is a relatively soft metal used in a range of alloys including bronze. Properties. Tin is a white metal at room temperature which is soft and highly rustresistant and fatigueresistant. Tin is nontoxic and highly malleable (able to be shaped). Tin alloys easily with other metals, has a low melting point and is easy to recycle.

The River Smelting And Refining Of Cleveland Processing Plant is a processing plant. The Southern New York Section of the Appalachian Highlands characterize the geomorphology of the surrounding area. Site identifiion and general characteristics. Learn about USGS mines. Copper, Iron, and Zinc Primary Commodity. Lead and Tin Secondary Commodity.

Lead extracted by the above method contains impurities such as silver, copper, tin, bismuth, gold and iron. It is refined by the following ..

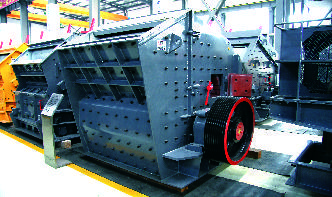

Tin smelting. Removing slag after tapping a furnace in a Southern tin smelter. The tin extracted from the ore has already been drawn off into floats for further refining. The slag is then run off to the right into ladles which will carry it to recooking operations. The slag is reintroduced to the process for further recovery of the metal. July.

Oct 29, 2021 · Electrolytic refining is the process of purifying using electrolysis. Copper, zinc, tin, lead, chromium, nickel, silver, and gold are just a few of the metals that can be processed electrolytically. A thick block of impure metals is used as an anode for electrolysis refining of impure metals, and it is connected to the positive terminal of the ...

A vitreous mass that separates from fused metals during smelting or refining of metalliferous material. Smelting Treatment of metalliferous material, typically a metal sulfide ore or concentrate, with sufficient heat to cause melting of the sulfide mineral(s) in the ore or concentrate such that a molten metal sulfide phase is formed.

Feb 01, 2022 · Results of an investigation aimed at optimizing the fire refining process for purifiion and extraction of antimony into a highgrade commercial metallic product are presented. Various refining agents were used for refining from lead, tin, iron, and arsenic. As a result of research, a method for fire refining of rough antimony was developed to obtain a high .