Straight grate technology is producing nowadays more than 75% of the DR grade pellets worldwide and it is the only technology capable to successfully process different source of iron ores assuring the maximum flexibility to the pelletizing plant.

straight grate pellet angola

single straight grate induration furnace or a train of three reactors consisting of a travelling grate, rotary kiln and cooler, known as the gratekiln process. The high temperatures produced in either process heat harden the green pellets, producing fired pellets which are strong enough to be used as blast furnace burden materials.

Green pellets while indurating in a straight grate induration furnace, pass through different thermal treatments, namely drying, preheating, heating and cooling. The firing of the pellet bed is downdraft using Corex gas and cooling is updraft using ambient air. Coke breeze is used as solid fuel to supplies the necessary heat for uniform heating of the pellet.

· The process to harden pellets by heating them up to the sintering temperature is called induration. There are three induration processes: GrateKiln, Straight Grate, and Vertical Shaft furnace, of which the first two are dominating whereas the shaft furnace is retreating. Figure illustrates a typical pellet firing process [22].

Iron Ore Pellets and Pelletization Process. Pelletizing of iron ore was started in the 1950s to facilitate the utilization of finely ground iron ore concentrates in steel production. For the pelletizing of iron ore there are two main types of processes namely, the straight travelling grate (STG) process and the grate kiln (GK) process.

Find Actizyme Pellets 900G CHS Delivering Australia Wide. Skip to main content. weborders; 1300 889 003 ...

· Two types of systems are usually used for induration of the ironore pellets: (a) straightgrate and (b) gratekiln process. A hearth layer of fired pellets is used in the former to protect grate bars from excessive heating. Fresh pellets .

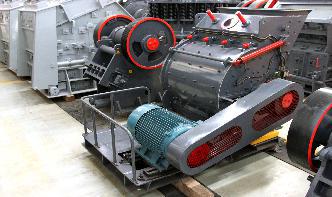

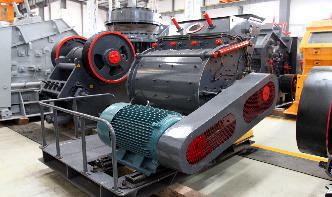

Straight grate pellet furnace . grate furnace kiln taconite stablesbusinessparkcoza. These are typically fed to a blast furnace or DRI plant as part of the process to is the only supplier of both Straight Grate and Grate Kiln pellet plants the making of iron and steel SEAISI the very large deposits of iron bearing rock called taconite which underlie much of the shaft.

· Fireplace grates are typically made from either steel or cast iron. Steel fireplace grates are typically more favorable for wood burning fires, while cast iron grates can be more favorable for use when burning either wood and coal. There are two main materials used for the construction of fireplace grates: Steel. Cast iron.

pellet plant process flow chart with straight grate technology. straight grate induration process for iron ore pelletizing. Read more availability pellet plant straight grate grate kiln ...

Straight Grate Technology Pellet Plant. x. Introduction to Outotec Pelletizing Technology 5:05. Learn about Outotec's Traveling Grate Pelletizing Plant the industry's leading induration technology for iron ore pellet production. x.

List of wood pellet mills companies, manufacturers and suppliers in Angola

IRON ORE PROCESSING BENEFICIATION Pellet Process Straight Grate Induration Dry Grinding. Get Price; Iron Ore Pelletizing Plant China. Essar Steel39s 6 Mtpa iron ore pellet plant at Paradip, Odisha, to The pellet plant is likely to meet Essar39s domestic requirement of iron ore pellets to feed its.

Overall OPEX savings: In a straightline cost comparison – biomass offered a 42% saving compared to the client's current coal usage and associated operational and maintenance costs.: Substantial emission reduction: A switch to biomass had a substantial emission reduction in harmful gasses like SO 2 and NO also had lower particulate matter emissions than coal .

Replacement New Style PorcelainCoated Match Pattern CastIron Cooking Grid for Pit Boss 1100 Pro Series Pellet Grills That Use 2 Grates. NOTE: Initially Pit Boss PB1100PS1 used to have three grates that were narrower. Those have been discontinued by the manufacturer and now these grills use two wider grates. If your e

· The use of biomass for energy can increase atmospheric concentrations of CO ₂ for years or even decades. Yet many countries grant it financial and regulatory support, ignoring the emissions from i ts combustion.. This chapter reviews the types of woody biomass feedstock that are burnt for power and heat, and the impact their emissions have on the global climate, in .

Iron ore pellets and Pelletizing processes – IspatGuru. Iron ore pellets and Pelletizing processes. satyendra February 23, 2013 5 Comments Grate kiln process, Iron ore fines, iron ore pellets, Pelletization processes, Straight kiln process, Iron ore pellets and Pelletizing processes Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size .

Both straightgrate and gratekiln furnaces have been accepted in the iron ore industry. ... The danieli iron ore processing technology combines the grate pellet plants productivity ore is received at the pelletizing plant:. Rea. Pilot Plant For Iron Ore Pelletizing