Blended elemental W–7 wt.%Ni–3 wt. %Fe powders were mechanically alloyed in a planetary ball mill and a heavy duty attritor. The structural and morphological characteristics of the asmilled powders were characterized by xray diffraction and electron microscopy techniques.

attritor vs ball mill

The effects of major processing parameters of attritor mills on ball milling efficiency (, minimum energy consumption with maximum milling progress) are investigated using discrete element modeling (DEM). The major processing parameters investigated include the size of balls, ball volume fraction inside the canister, ball milling velocity, and design of the impeller shaft .

· A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size.

· In wet ball milling, biomass fibers swell with water and hydrogen bonding between nanofibers weaken, resulting in defibrillation of the bundle of nanofibers. In terms of final particle size, wet ball milling is more suitable to reduce the particle size below 1 .

· Jul 14, 2014 04:45 PM 15. Hello guys. I would just like to know what is the difference between a food mill and a grinder? Are there any differences in the both of them or are they the same? Want to stay up to date with this post?

difference between sand mill and ball mill. difference between sand mill and ball mill, MIKRONS is an Original Equipment Manufacturer of machineries such as Attritor, Agitator, Ball mill, Bead mill. Get Price

· Today we will learn about difference between sag mill vs ball mill. A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding, crushing or cutting. This commutation is an essential part of many processes. Various kinds of mills are there with which different material processing takes place.

An attritor mill (1) comprises a grinding chamber (5) and a rotor (7) having a plurality of radial arms (9, 9', 9"). The attritor mill (1) is arranged to grind, mince, triturate or micronize a material to be treated, such as for example urban solid waste, food scraps or more generally the socalled "wet waste", by carrying out the following steps: S1) mixing the material to be treated with ...

Optimization of mill performance by using online ball and pulp measurements by B. Clermont* and B. de Haas* Synopsis Ball mills are usually the largest consumers of energy within a mineral concentrator. Comminution is responsible for 50% of the total mineral processing cost. In today's global markets, expanding mining groups are trying

Difference Between Sand Mill And Attritor. Difference between sand mill and attritor. which enables us to see how the attritor fits into the family of mills for example ball mills use large media normally 12 or larger and run at a low 1050 rpm the other mills such as sand bead and horizontal use smaller media from 03mm to 2mm but run at a very ...

SEM micrographs highlighted that the planetary ball mill had a better particle size reduction, while the BET surface area results indied a greater surface area loss compared to the attritor mill. XRD patterns and 27Al MAS NMR spectra showed that depending on the intensity of the milling conditions the phase transformation was mechanically activated and most of the γ .

· The present model focuses on experiments using an attritor mill, model 01HD by Union Process. In this mill, milling balls are agitated by a steel impeller rotating at a designated speed. In the experiments, the impeller was set to rotate at 400 rpm. The attritor mill contains a builtin data acquisition unit by Baldor.

The difference between Raymond mill and ball mill is mainly reflected in two aspects: The scope of appliion. Raymond machine widely used in the Mohs hardness is less than, high fine powder processing humidity below 6% non inflammable and explosive mineral, chemical, construction and other industries more than 280 kinds of materials;

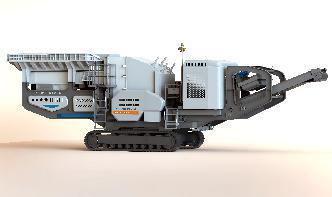

Attrition Milling The attritor, also referred to as a stirred ball mill,1 is a high speed mill used for rapid particle size reduction. Attritors have been developed for both wet and dry grinding appliions, and are available in batch and continuous loading configurations. The attritor uses a stationary vessel charged with grinding media ...

This study reports on the mechanical processing (attritor ball milling) in argon and nitrogen gas environments of (a) iron powder and prealloyed ironâ2 wt.% aluminum powder, and .

MIKRONS ® Attritor is used for producing fine homogenous dispersions quickly repeatedly under controlled conditions. Used for the manufacture of ceramics, inks, paints,coatings, metal oxides, ferrites, chocolates, chemicals pharmaceuticals. The Attritor is often referred to as a agitated ball mill.

Recently, ball milling process is performed in different types of high energy ball mills such as vibrator mills, planetary ball mills, attritor mills, tumbler ball mills etc. Among them, the vibrator and planetary mills have been used for the processing of small amount of materials (less than 100 g) within a short span of time.

Planetary ball mill is a most frequently used system for mechanical alloying since only a very small amount of powder is required. Therefore, the system is particularly suitable for research purpose in the laboratory. The ball mill system consists of .

MIKRONS ® Attritor is used for producing fine homogenous dispersions quickly repeatedly under controlled conditions. Used for the manufacture of ceramics, inks, paints,coatings, metal oxides, ferrites, chocolates, chemicals pharmaceuticals. The Attritor is often referred to as a agitated ball mill.

Answer (1 of 3): The ball mill is generally composed of a cylinder, a lining plate, a feeder, a discharger, a hollow shaft, a bearing, a transmission device, and a lubriion system. In the ball mill, when the cylinder rotates around a horizontal axis at .

Process Mills Jar, Ball, Pebble and Vibratory Mills Attritors, Media Mills, 2 3 Roll Mills. Crushers, Pulverizers, Size Reduction. Screeners, Sifters, Sieve Shakers. Spray Dryers, Drying Systems. Kilns, Furnaces, Ovens. Motors and Variable Speed Drives. Facility Equipment Miscellaneous. Powder Press Parts Stokes R4 526 Press Parts