· John G. Lenard, in Primer on Flat Rolling (Second Edition), 2014 Power System. Integrated steel plants usually provide a part of their electric power requirements with their own generating equipment, the power being produced using byproduct fuels. Due to the large amount of power required by the mills and the concentration of this load, electrical .

enregy required for roller mill

fabriion required. ... Structural sections from the rolling mills may require surface cleaning to emove mill r scale prior to fabriion and painting. Hand preparation, ... In this method, the cutting energy is produced electrically by heating a gas in an electric

enregy required for roller mill. energy required for roller mill energy required for roller mill 24T Mill grinding Wikipedia A mill is a device that breaks solid materials into smaller pieces by grinding crushing or cutting Such comminution is an important unit operation in .

Pgs: 2734 Torque required for Hot Rolling: Torque = knm Power required for Hot Rolling: Work done = Power =W Power = Kw Fig.: 3 Drafted view of gear Fig.: 4 Centre gear Mayuur S. Shelke, Prof. Kshirsagar 33 , INTERNATIONAL JOURNAL OF RESEARCH IN AERONAUTICAL AND MECHANICAL ENGINEERING January 2014.

classifier .Fluid energy mill reduces the particles to 1 to 20 micron. To get a very fine powder,even upto five micron, the material is pretreated to reduce the particle size to the order of 100 mesh and then passed through fluid energy mill. Uses The mill is used to grind heat sensitive material to fine powder.

Roller Mill and Hammermill on Corn US #2 Yellow Corn 300 400 500 600 700 800 900 1000 2 3 ... Increasing energy costs, increasing customer awareness of ... In any roller mill, the rolls will need to be removed periodically for recorrugation.

K = 1/2 * I * omega^2. where omega is speed of rotation (radians/sec), and I is the moment of inertia you have decided to use, depending how that .

· (3)Attrition mills, exattrition mill. (4)Tumbling mills. exball mill. C. Ultrafine grinder, exfluid energy mill. D. Cutting machine, ex cutter mill. 4 5. TECHNIQUES ROTARY CUTTER MILL MORTAR AND PESTLE ROLLER MILL HAMMER MILL BALL MILL FLUID ENERGY MILL COLLOID MILL EDGE RUNNER MILL END RUNNER MILL 5 6.

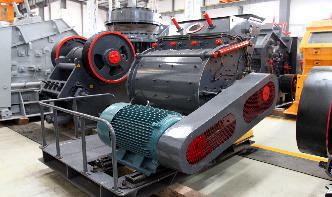

enregyenregy required for roller mill. Our roller mills are capable of comminuting very hard through to soft products homogeneously and with a minimum fine material content depending on requirements to a reduction ratio of between 15 and 115 and our doubleroller mills to a Mohs hardness of up to approx 85 Singleroller mill

· Manufacture the roller for rebar rolling mill, Bar rolling mill, TMT Rolling mill, Section rolling mill in China Email: renxiaohua1 Wechat/WhatsApp: + Like Sign in to like ...

· While the energy consumption in modern rice mills generally vary from 18–26 kWh/t for raw and 20–30 kWh/t for parboiled paddy, sheller and huller mills required higher energy. Rice mills having elevators for material handling consumed 7–10 kWh/t and 24–25 kWh/t of mechanical energy for parboiling and drying, respectively.

Reheating furnace for steel rolling mill line is a device (an industrial furnace) that heats a material or a workpiece (generally a metal) to rolling forging temperature in the metallurgical industry.. Structure and composition. According to the distribution of furnace temperature, the furnace is divided into preheating section, heating section and heating section along the length .

A roller mill requires 1540% less energy to produce a 700 micron particle size than a hammermill, but if grain types are to be changed frequently, the roller mill will need to be adjusted for each grain. A roller mill will produce grain with a more uniform particle size (less fines and large particles) than a hammermill.

roller mill used in cement industry. Energy Balance For Roller Mill Used In Cement Production. energy balance for roller mill used in cement production energy required for roller mill harambeehealthcenter energy required for roller mill requirements for the cement industry in the future are to reduce the use of energy

Roller mills are more energy efficient for producing a product with large particle sizes (+1800 microns), but similar to hammer mills when the target particle size is 600 microns or below. Roller mills with no roller speed differential are used to process tempered, steamflaked or steamrolled grain. Roller mills generally

Energy Consumption in the mill sections UNITS ELECTRICITY % KW/H INTAKE SECTION 0,4% CLEANING SECTION 7,7% SECOND CLEANING SECTION 3,0% MILLING SECTION 10,8% Roller Mill 49,6% P. Fan 17,1% FLOUR PACKING SECTION 10,5% BRAN PACKING SECTION 1,0% Total 100,0% Do improvement in these area

• – Mills and calenders in the rubber and plastics industries • – Mechanical power presses • – Forging machines • – Mechanical powertransmission apparatus Control of Hazardous Energy (Lockout/Tagout): 29 CFR Hand and PowerTools: 29 CFR Part 1926, Subpart I

required energy and power for hot reducing of tubes on a stretch reducing mill (SRM) with the final aim of an optimal sizing of the mill drives. Effective calculations are shown as methodology examples for the case of stretch reducing of a Φ blank into a tube. In order to evaluate the validity and accuracy of the suggested Φ

Energy Management In Flour Plants Miller Magazine. Energy requirementconsumption in flour plants the milling of wheat into flour is the most energy required process in flour plants so it is important to control the energy consumption of flour mill milling is the process by which the endosperm is extracted from the grain by passing it through series of rollers rotating at .

Roller Mills Roskamp roller mills deliver a consistent, uniform grind for varied appliions. Engineered to support your need for energyefficient, precise particle size control, Roskamp roller mills are built on a strong foundation and equipped with solid rolls for long life and reliability. They're sturdy, easy to

However, in hotrolling mills, water used for descaling and cooling steel (process water) and water used for cooling rolls and bearings (cooling water) were reported together. Inasmuch as the steel indus try generally considers all water used in rolling mills as cooling water, it is reported as such in this report.