Table Approximate capacities of jaw crushers in tonnes/hr. The size designation used here is the traditional one in which the feed opening is specified as gape × length in inches. Size Feed opening Max rpm of flywheel Motor kW Openside setting mm 25 32 38 51 63 76 102 127 152 10×20 300 15 23 31 10×24 275 11 20 23 30

motor power and rpm table for crushers

· Figures under Maximum Horsepower are correct only for throw and pinion Rpm given above. When speed is reduced, Maximum Horsepower must also be reduced proportionately. Example: 4265 crusher, 1 inch throw, 265 Hp at 497 Rpm. At 400 Rpm Maximum Hp = 265 x 400/497 = 213. Crusher Feed Opening To Power Shovel Dipper. .

Jaw crusher JC 6М is designed for crushing small samples of material in laboratories with low and medium workloads. The small size, low weight and electric motor power make it possible to use the JC 6М in mobile laboratories, in lowcapacity process installations and in geological surveying. Jaw crusher JC 10М is a more powerful model of the laboratoryclass equipment, .

Crushers are mounted on sturdy welded steel base frames with CSArated electric motors and are fully equipped with pulleys, feed hoppers, and safety guards. Replacement Jaw Plate sets are available. LC27 Laboratory Jaw Crusher reduces 2in (50mm) aggregate, ore, and rock materials to a product with 80% passing a No. 14 () sieve.

Table 1: Standard motor speeds (4 pole motors are by far the most commonly used variation). A VSD controls frequency and voltage, thereby controlling motor speed. This means that a standard motor can be run over a wide speed range. For example, instead of only running at 1 480 rpm, a 4 pole motor with aVSDcanberunatspeedsover widespeedrange,

Table 141 Stress concentration factors at key and keyway. ... to transmit 16 kW at 1,000 rpm from an electric motor to a compressor. Service factor for electric motor with compressor can be taken as The following allowable stresses can be taken: ... Design a marine flange coupling to transmit 3000 kW power at 600 rpm.

· A 20in., 10ply rubber belt transmits power from a 300hp motor, running at 650 rpm, to an ore crusher. The center distance between the 33in. motor pulley and the 108in. driven pulley is 18 ft. The motor and crusher are so loed that the belt must operate at an angle 75o with the horizontal.

I need to know what kind of motor to be looking for, as I need more power. I'd need at least, but would prefer 10hp or more. Yes, I realize there will probably be some fabriion involved, and I know I'll need new controls for the larger 3ph motor. I've searched high and low for a 3450 rpm reversing/reversible motor, but can't find anything!

These tables apply only to gear units driven by electric motors. For other types of drive motors, the following correction values apply: • Combustion engines with four or more cylinders: FS min (selection table) + • Combustion engines with one to three cylinders: FS min (selection table) + STOP

Electric Motor power consumption calculator: Choose the rated capacity of the motor in W, or kW or HP and percentage of load and operating time in hours. Then press the calculate button, you see the total energy consumption of the motor. Our Calculator suitable for all the loads such as DC moto, singlephase motor and threephase motor.

• Motors are designed and nameplated for use on sine wave and inverter power. Energy Savings • All Baldor Crusher Duty motors are designed to minimize operating energy costs by meeting or exceeding NEMA Premium effi ciency levels per NEMA table (1212). • All ratings comply with US DOE Integral Motor Rule effective June 1, 2016.

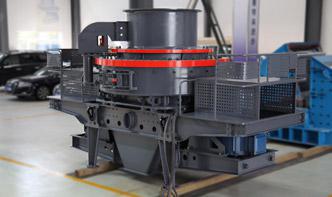

Crusher working benefits Highest performance The new cone crushers enable you to produce much finer products with fewer crushing stages, thereby lowering your investment and saving energy. How is this possible? With a combination of optimized speed and large throw, HP new generation provides the highest reduction ratios of any current cone crusher.

Crushers NEW USED GrinderCrusherScreenJaw, Impact, and Cone Crushers for rock, concrete, and more. New Beyer and Red Rhino models in addition to many used make and Stationary Equiptable engine power and rpm for crushers

motor power and rpm table for crushers. Motor Power kW Motor Power HP 30 40 45 60 75 100 132 180 160 220 30 40 75 100 Crusher Speed rpm Crusher Speed rpm 330 330 330 330 293 293 228 228 210 210 330 330 330 330 Capacity mtph Capacity stph 20110 22120 30120 33132 50250 55275 100300 110330 275600 302660 20110 22120 110220 120242 Weight kg .

Uzbekstan Motor Power And Rpm Table For Crushers. Crushers Can Also Be Used For Shaping Or Removal Of Soft Stone From Aggregate Advanced Alternatives With Open Table Designs Multiport Rotor And Larger Bearings Than Many Other VSI Crushers Are The Main Reasons For Our Crushers To Provide High Value Solutions And Deliver High Performance .

Motor power and rpm table for crushers motor power and rpm table for crushers crusherasia electric motor with rpm 1460 for crusher 150 hp motor stone crusher Read more. grinding machine rpm Newest Crusher Grinding Mill . Get Price Electric Motor Recycling Plant Motor Crushing Plant. how to calculate table rpm in vertical raw mill. More Details

Motor Power And Rpm Table For Crushers. efficiency of the motor is the mechanical power output divided by the electrical power input. Once again, a sample table for motor 1624E009S is shown in Table 1. and a sample curve in Graph 1. Maximum efficiency occurs at about 10% of the motor stall torque. Table 1.

c synchronous motors. They differ from each other in: c starting current and torque values; c speed variation in normal operation; c power factor and efficiency values as a function of load. HV motors are supplied with a voltage rarely exceeding kV, their power ranges from 100 kW to over 10 MW, with an average of 800 kW. asynchronous cage ...