Milling Ore Once at the production facility, it is put through a hammer mill to reduce it down to 200 mesh minus in particle size, then fluxed and roasted to reduce ore to an oxide. It is then ball milled with steel balls to a nano particle size, to achieve the highest yield and also the highest concentration level of whatever metal or element is desired to be processed.

roll mill for ore processing

Drum Drying also known as Roll Drying is a continuous process that creates dry powders and flakes from a liquid feedstock. The liquid feed is sprayed onto or in between two rotating drums. The drums are heated internally with steam to increase the surface temperature. As the material is sprayed onto the drums, it sticks and dries to the surface.

LONGSTANDING EXPERIENCE AS A LEADING SUPPLIER OF COLDROLLING MILLS As a lifecycle partner for coldrolling mills, Primetals Technologies offers complete solutions and support packages for coldrolling mills that extend from the initial investment idea, to mill planning, layout, engineering and construction, up to turnkey plant installations and fullscale .

Rolling mill – Any of the mills in which metal undergoes a rolling process. For plate, sheet and strip, these include the slabbing mill, hotrolling mills, coldrolling mills, and temper mills. Any operating unit that reduces gauge by appliion of loads through revolving cylindrical rolls; operation can be hot or cold.

Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and grain mills are an alternative to traditional millstone arrangements in mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the ...

• mill scale (small flakes of iron oxide from the rolling mills); and • flue dust and precipitator dust (fine ore bearing particles) collected from the blast furnace and BOS furnace exhaust gases. This moistened mixture is coarsened by a granulation process and is then spread as a layer up to

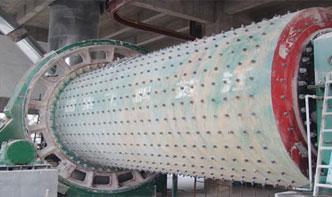

It accounts for up to 40% of the total power consumption in mineral processing plant operations. So, selecting the efficient solution for grinding section is very important. Prominer provides ball mill / rod mill grinding system which is widely used in various types of ores' beneficiation, electricity, cement and chemical industries.

Ball Mills 【Capacity】 T/H 【Advantages】Designed for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, a large volume of processing capacity 【Max Feeding Size】 <25mm 【Discharge Size】 【Types】Overflow ball mills, grate discharge ball mills 【Service】 24hrs quotation, custommade .

· Autogenous and SemiAutogenous Mills. Autogenous (AG) and SemiAutogenous (SAG) milling has seen increased use in recent years, especially in large mineral processing operations. These mills typically have a large diameter relative to their length, typically in the ratio or 2 or to 1. AG mills employ ore as the grinding media.

Mineral Processing Technology mineria procesamiento de minerales. Mineral Processing Technology An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery, by Barry A. Wills, Tim NapierMunn

Nelson Machinery sells new used grinding mills including ball mills, SAG mills, tower mills, Raymond roller mills. Equip yourself with the gold standard

Inventory ID: 6CKT01a. UNUSED FL 27' x 46' ( ID x L) Ball Mill with MW (20500 kW/27,491 HP) GMD Motor

· Sulphide coppergold ores are usually sorted by flotation. The standard comminution process to grind the ore to flotation fineness, mostly consists of coarse crushing followed by SAG milling or wet ball mill circuits, or alternatively multiple stage crushing followed by rod and ball milling.

Gold Ore Roller Mills abbronzaturaesteticaverona. Hard Rock Roller Mills Faq About Gold Ore Grinder. Gold ore processing mill crushes quartz and mining rock ore to release gold our gold stryker gs 4000hd is a high quality made here in the usa flail impact gold mill and can process and crush up to 23 tons of rock a day all the way down to 300 mesh through the mill to .

In this process, slabs whose surface scale share has been removed are made into rolled materials with the proper shape, thickness, and width. In the entry and exit area of the roughing mill, an edger rolls the strip in the width direction using an Automatic Width Control (AWC) system. 3. Finishing Rolling

Corex, the unique smeltingreduction process allows for the costeffective and environmentally friendly production of hot metal from iron ore and coal. In the Corex process, all metallurgical work is carried out in two separate process reactors—the reduction shaft and the melter gasifier.

Three Roll Mill Related Articles, Mixing Technology Insights and Whitepapers. Best practices for safe and efficient three roll milling. Create smooth, speckfree pastes in your Three Roll Mill. Upgrade your ball mill process by switching to a three roll mill.

roll mill for iron ore processing, Utilising of the oiled rolling mills scale in iron ore sintering process Dec 24, . live chat. Mill (grinding), where it then falls off the plates onto the rest of the ore charge SAG mills are, in a grinding process Like ball mills,, roll mill; Vibratory mill; VSI.

Rod mills operate at lower speed than ball mills since the rods are rolled and not cascaded. For an equivalent grind, a rod mill uses less steel than a ball mill because of the lower speed and better contact between the media and ore. The rod charge must be maintained in good working condition, and broken and worn rods must be removed.

In the hot rolling process, the cast billet is reheated to a temperature of 1100 1200°C, and then rolled through a rolling mill to reduce its crosssection (Figure 4). A rolling mill consists of a series of stands, each of which consists of two cylindrical rolls into which grooves are cut to accommodate the material being rolled.

gold and silver rolling mills germany. 29/10/2016· Jewelry Rolling Machine Superb Electromachinery Co., . 10HP metal plate rolling mill to roll copper, gold, silver, etc. Jewelry rolling mill for sheet, it adds metal through extrusion, the metal thickness thinning, the surface is wheel surface is smooth, the product surface is smooth.

Loesche Mill LM, Slavno, Poland, 2006 Over more than 100 years Loesche has built up a wealth of experience in the grinding of coal, cement raw material, clinker, slag, ores and various industrial minerals such as: • Limestone • Dolomite • Marble • Chalk • Quick lime • Barite • Betonite • Colemanite • Phosphate rock