Ball Mills are the most effective laboratory mills for rapid batchwise comminution of mediumhard, soft, brittle, fibrous, temperaturesensitive and moist samples down to the finest particle size. The comminution of the material to be ground takes place through impact and friction between the grinding balls and the inside wall of the grinding ...

ball mill grinder with mm

20/02/2017 · Type CHRK is designed for primary autogenous grinding, where the large feed opening requires a hydrostatic trunnion shoe bearing. Small and batch grinding mills, with a diameter of 700 mm and more, are available. These mills are of a special design and described on special request by all Ball Mill Manufacturers. Types of Grinding Mill Manufactured

Quality Ceria Zirconia Beads manufacturers exporter buy Mm Ball Mill Grinding Media Ceria Zirconium Oxide Beads For Painting from China manufacturer.

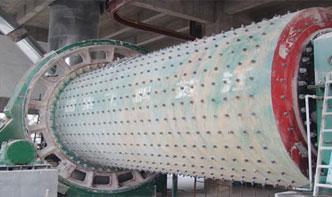

The Grinding ball mill is the most widely used equipment in industyr grinding, the grid type ball mill and overflow ball millis used in the mineral processing industry and other industrial field .Dry type grid type ball mill is mainly used for industrial milling, mainly used for .

18/03/2022 · 120mm Grinding Media For Mining for semiautogenous ball mill, with the rapid development of the society, natural resources such as energy ores are becoming less and less, the mining environment is becoming more and more difficult, and the required cost is getting higher and higher, how to reduce the consumption of energy mining And cost investment has .

Part # Description. CLAMPS. 8015. Clamp For Slurry Grinding Details. GRINDING MEDIA. 3112. Methacrylate Grinding Balls, 3/8 In. ( mm) Details. 3114SB. Stainless ...

23/09/2011 · Grinding was conducted in a ball mill with a displaced axis of rotation and an inner diameter of 170 mm. Steel balls 23 mm in diameter were used as grinding bodies. The grinding time was 4 and 8 h and the charge ratio 1 : After grinding, the powder was subjected to a .

The grinding jars of the mixer mill MM 400 perform radial oscillations in a horizontal position. The inertia of the grinding balls causes them to impact with high energy on the sample material at the rounded ends of the jars and pulverize it. Also, the movement of the jars combined with the movement of the balls result in the intensive mixing ...

In a ball mill of diameter 2000 mm, 100 mm dia steel balls are being used for grinding. Presently, for the material being ground, the mill is run at 15 rpm. At what speed will the mill have to be run if the 100 mm balls are replaced by 50 mm balls, all the other conditions remaining the same? Calculations: The critical speed of ball mill is ...

Ball Mill. Ball mill, also called grinding mill, ball grinding mill, is the key equipment to grind crushed materials into fine powder 2075 micrometer. It has grate type and overflow type. ≤25mm Feed Size. Motor Power. –90 t/h Processing capacity. Complete solutions, quality equipment and expert services. Get Quotes Leave ...

Compared with ball mill machine,rod mill can accept larger feed particle size (upper limit is 15 to 25 mm); Suitable for coarse grinding, the upper limit of particle size of rod mill is 1~3 mm; high production capacity in coarse grinding.

23/12/2013 · Introduction: 'Ball milling is a method used to break down the solids to smaller sizes or into a powder. A ball mill is a type of grinder which consists of a cylinder. It is used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. The cylinder rotates around a horizontal axis.

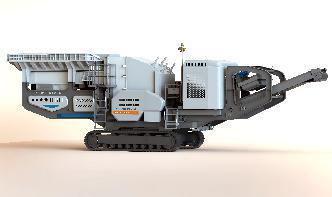

Ball Mills. Ball mills have been the primary piece of machinery in traditional hard rock grinding circuits for 100+ years. They are proven workhorses, with discharge mesh sizes from ~40M to <200M. Use of a ball mill is the best choice when long term, stationary milling is justified by an operation. Sold individually or as part of our turnkey ...

Wet Grid Ball Mill | Capacity: Feed Size: ≤25 mm. Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc. The size of ore shall not exceed 65mm and the best feed size is under 6mm.

Highenergy ball mill with dual clamps that accommodates sample sizes ranging from 10 grams. Ideal for grinding dry, brittle samples, mechanical alloying, slurry grinding, blending powders, and mixing emulsions. Typical samples include rocks, minerals, sand, cement, slag, ceramics, alyst..

Ball mill grinding is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liners and ripple liner and different specifiions of steel balls in the chamber.

Ball Grinding Mill. Capacity:20200 T/H. Feeding size:25 Mm. Output Size:30400 Mesh. Brief Introduction of Ball Mill Grinding: Ball mill Grinding can divide into 2 types, wet ball mill grinding and dry ball mill grinding. Ball mill grinding is a mineral processing machine for milling the materials into powders after they are crushed. It ...

08/03/2021 · Overflow discharge ball mill can grind ores into the size under mm, so it is very suitable for the second grinding system. The capacity of it is about 15% lower than grate discharge ball mill in the same specifiion, and the loaded grinding medium is .

22/05/2019 · Therefore, in the rolling ball mill, the grinding efficiency is increased as the ball diameter decreases. It has been proven that the highest grinding efficiency can be obtained with a small ball of .mm diameter. However, the ball diameter is too small to wear too fast, and it is also difficult to discharge due to the small gap of the ball.

Micro Ball Mill MM 1100 is crafted for the Modern Laboratory. With digitally adjustable speed fast grinding technology Labindia Micro Ball Mill achieves fineness up to less than 5 µm Feed Size less than 10 mm.

Ball Mills 40 – 250 litres. There are 4 different sizes of porcelain drum type mills available. They can be used for wet as well dry processes. The drum consists of a porcelain body without joints. We recommend this type of drum when the contents is frequently changed, because it is very easy to clean. The height of the stands can be adjusted ...

Dry ball mill is a grinding equipment that uses dry ball milling process to grind materials. Different from the wet ball mill, the dry ball mill does not need to add water when performing the grinding operation, only relying on the impact and crushing effect of the grinding media on the material to grind the material.. The finished material of the dry grinding ball mill is dry .

The grinding media are iron and steel balls for a ball mill with a diameter of 15150 mm; carbide balls with a diameter of 820 mm; iron or steel cylinders (such as "cylpebs"); round steel rods with a diameter of up to 130 mm and a length corresponding to the length of the mill drum; and silicon or ore pebbles up to 200 mm in size, large pieces ...